01

Overview

Sabre Valves are dedicated to sustainable and environmentally friendly valve solutions. With over 45 years of expertise and our strong global network, we are well positioned to support our customers succeed in the application of hydrogen valves across many fields.

We designs valves suitable for a wide range of hydrogen applications, including hydrogen generation, fuel cells, compressors and pumps, fuelling systems (ISO 19880-3), storage, pressure vessels, piping systems, and transportation.

We can manufacture valves to any design specification, including with your choice of materials, within a very short lead time.

02

about hydrogen

Hydrogen is the most abundant chemical element, contributing an estimated 75% of our universe’s mass.

Despite its abundance, and being present in nearly all compound substances, due to its atomic weight it’s very scarce as a gas; less than one part per million by volume.

Hydrogen is the most abundant chemical element, contributing an estimated 75% of our universe’s mass.

Despite its abundance, and being present in nearly all compound substances, due to its atomic weight it’s very scarce as a gas; less than one part per million by volume.

Hydrogen has a light atomic weight and molecule structure, is a colourless, odourless gas and therefore cannot be detected, it burns with an invisible flame.

Hydrogen is playing an increasingly important role in sustainable energy supply. Currently, most hydrogen is produced from fossil fuels (specifically natural gas) and electricity (from the grid, renewable sources such as wind, solar, geothermal or biomass). The challenge is harnessing this volatile gas on a large scale.

Hydrogen being a volatile gas, presents substantial risks. A valve suitable for hydrogen applications comes down to three key manufacturing components; the materials used in construction, the sealing components and the qualification tests.

03

Design and manufacture

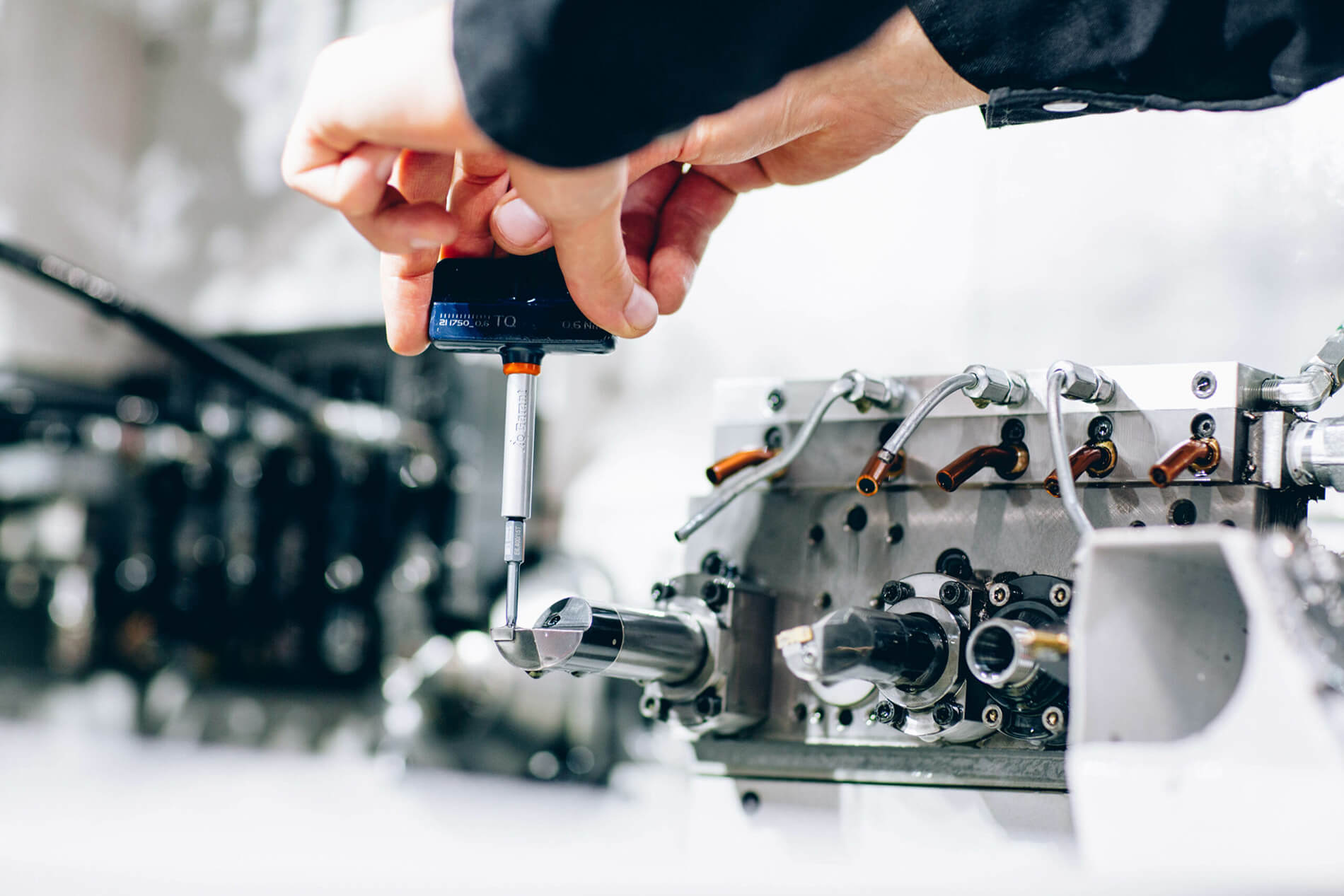

Sabre Valves design and manufacture in accordance with the highest international standards. Standards that can accommodate the extreme operational conditions, such as high pressure, very low temperatures, and, in this case a highly combustible gas.

This places an emphasis on the reliability and performance criteria of the valves. Our valves are qualified for fugitive emission to ISO 15848-1 and fire certified to ISO 10497.

Hydrogen is known to cause embrittlement, a phenomenon where hydrogen infiltrates the metal lattice in certain metals, resulting in eventual cracking. This poses a significant safety hazard and environmental risks, particularly in critical components like valves. It’s vital to select valve materials compatible with hydrogen. Stainless steel, titanium, and high-strength alloys are commonly used due to their resistance to hydrogen embrittlement

Material compatibility is of utmost importance, as is the selection of sealing components. Hydrogen, with its unique characteristics, demands a nuanced approach to valve selection, while keeping safety a top priority.

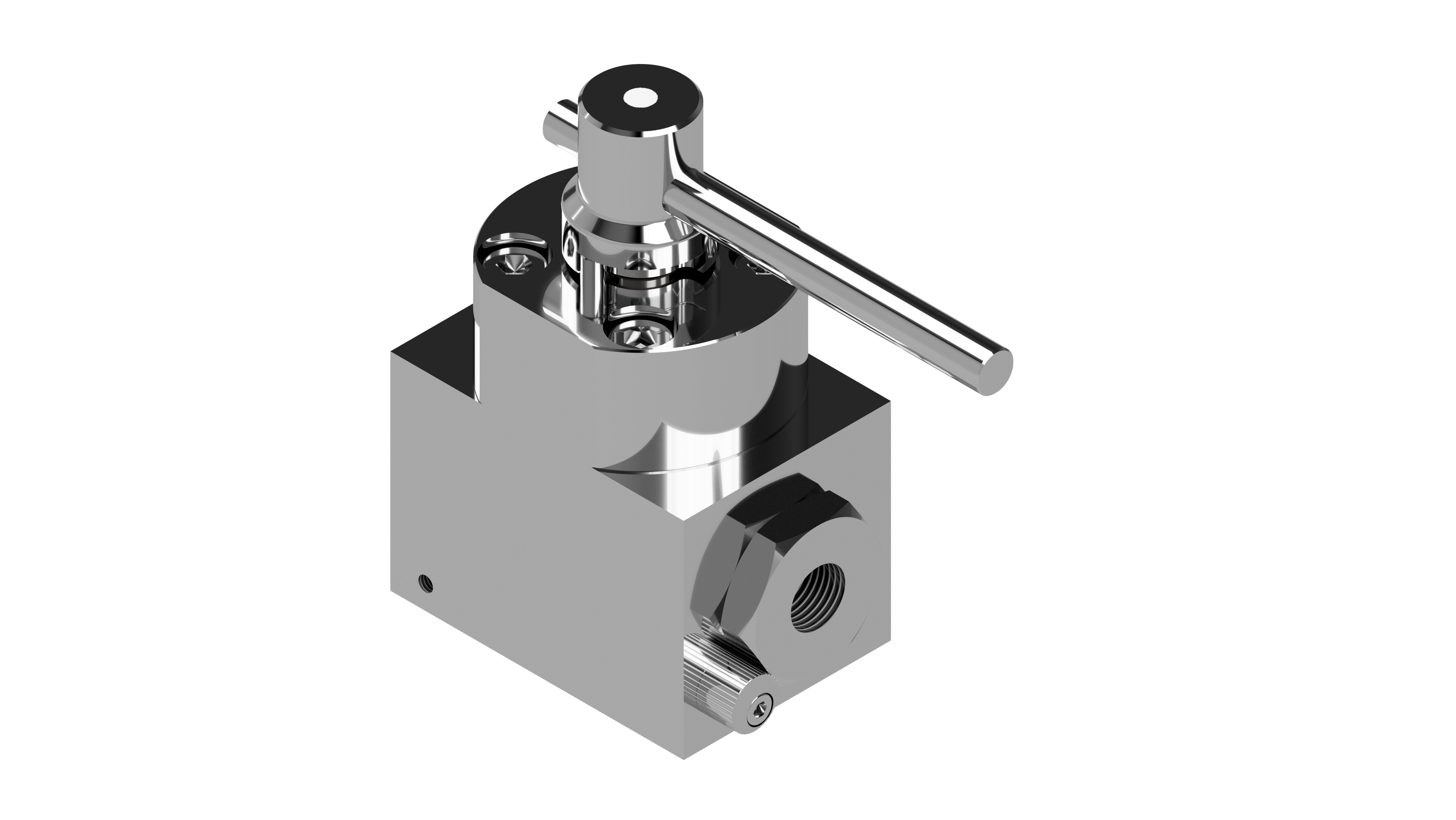

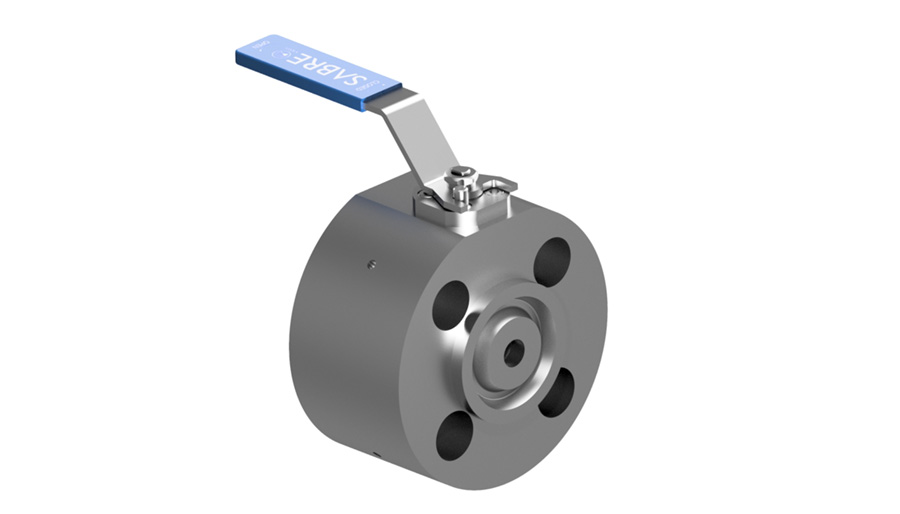

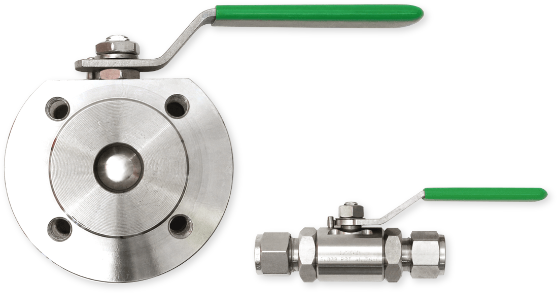

Full & reduced bore floating Ball Specifications

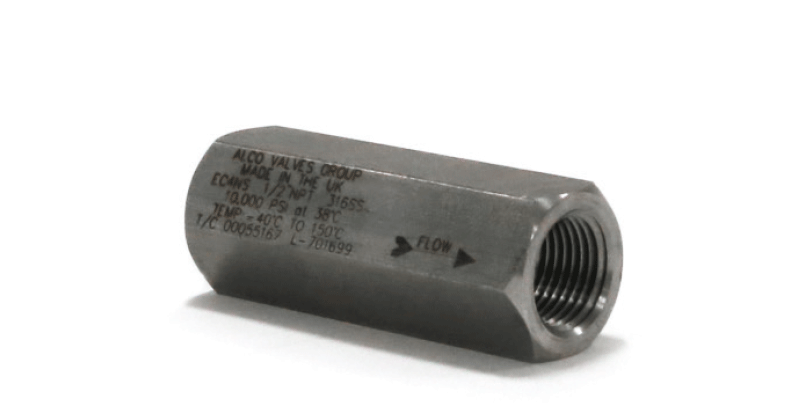

Size: 1/2″ To 1″ NPT / BSPP / BSPT

Pressure rating: 6,000 & 10,000 PSI

Materials: 316/316L Stainless Steel

Temperature: -100 To + 350 Deg C

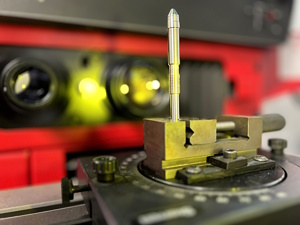

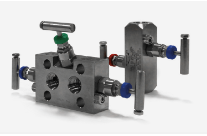

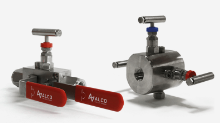

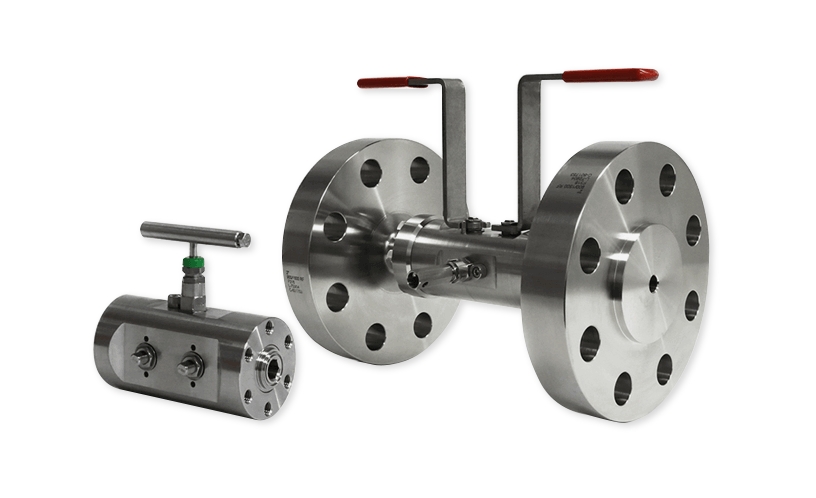

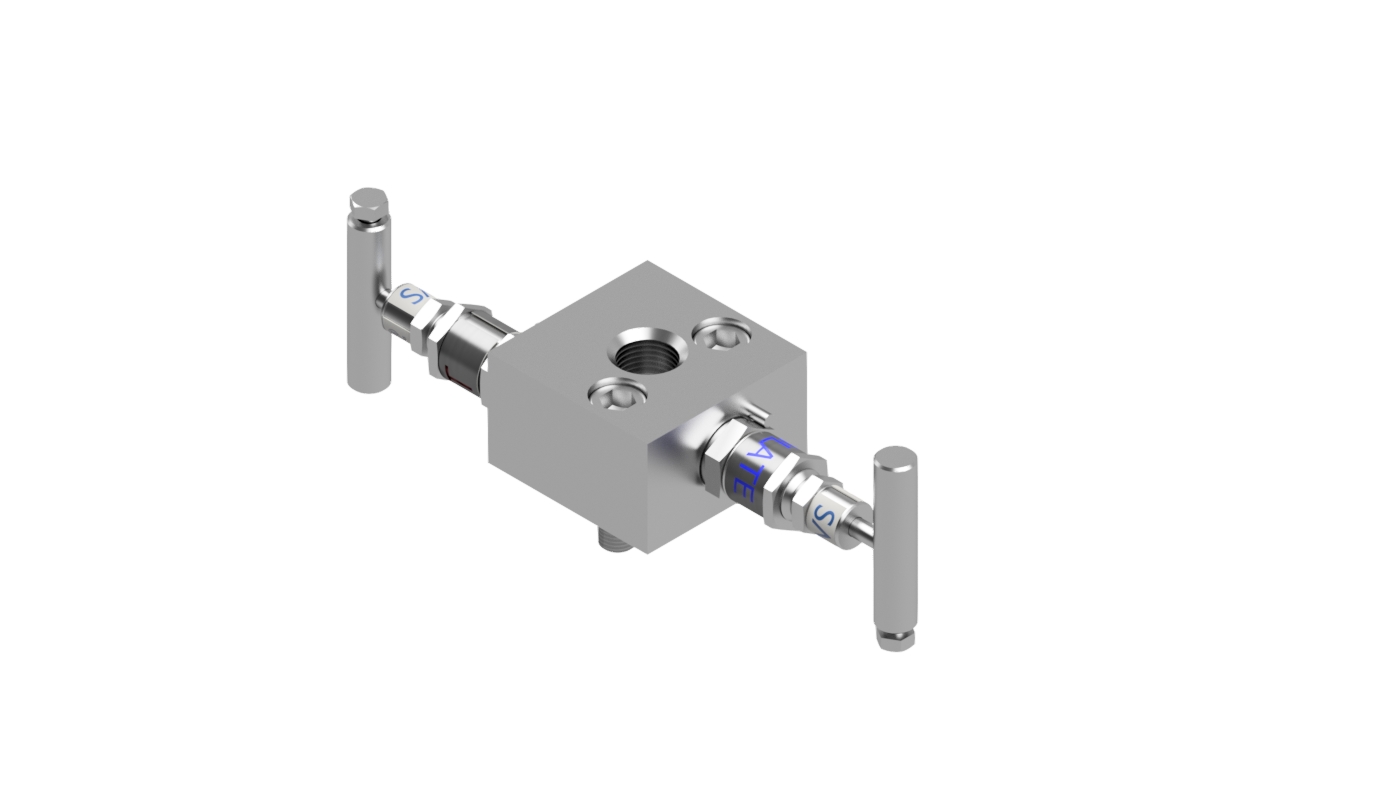

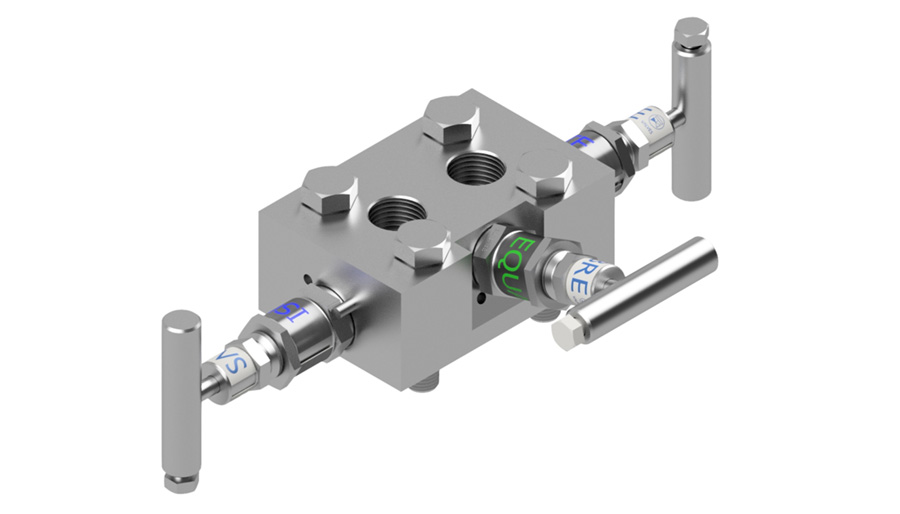

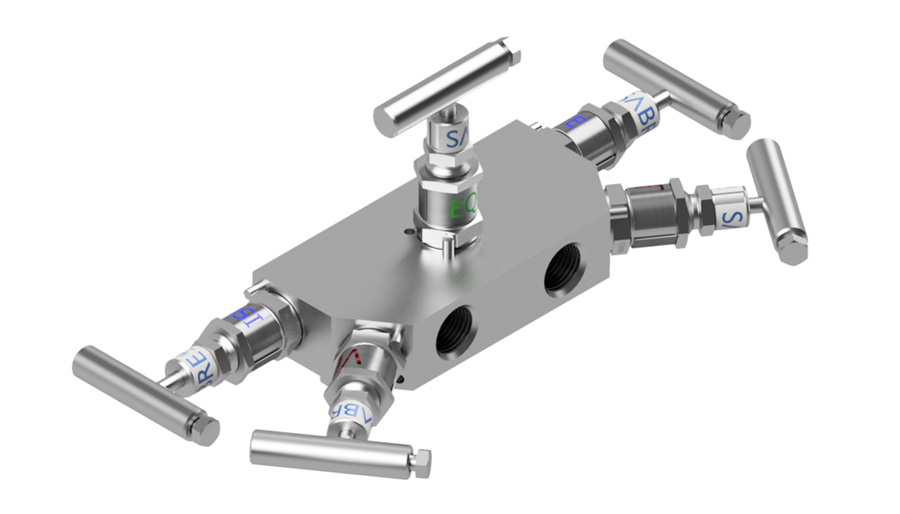

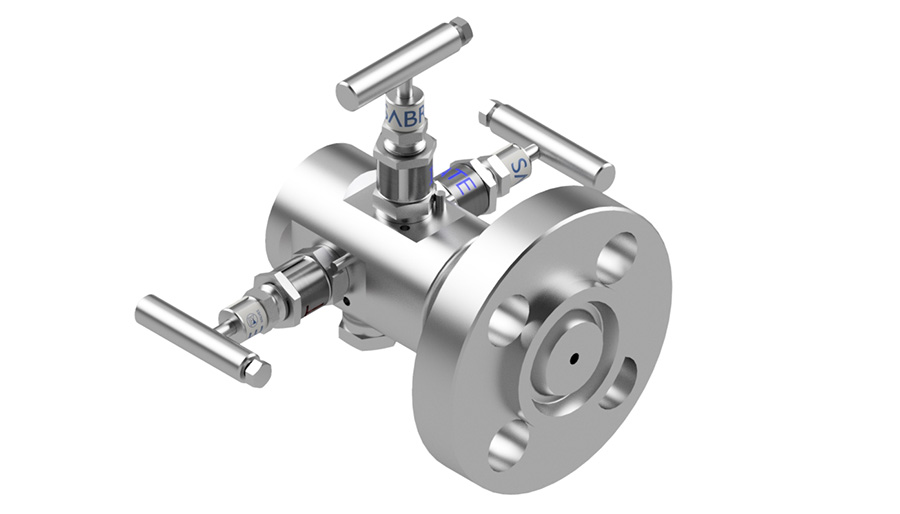

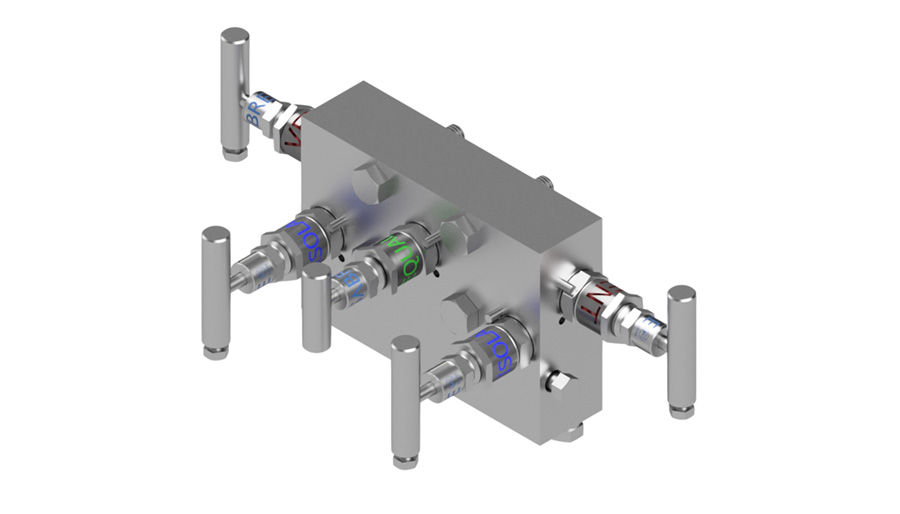

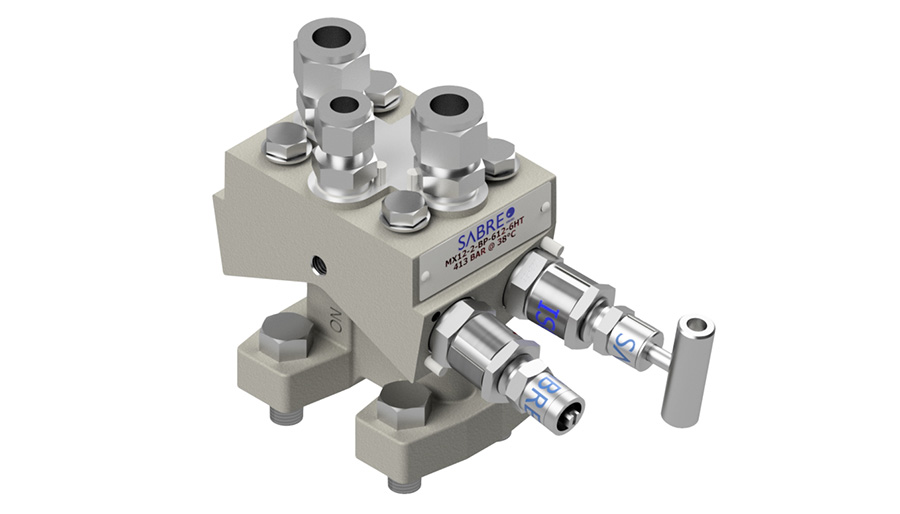

Needle Valves & 2, 3 & 5 valve manifolds Specifications

Size: 1/4″ To 1″ NPT / BSPP / BSPT

Pressure rating: 6,000 & 10,000 PSI

Materials: 316/316L Stainless Steel

Temperature: -100 To + 540 Deg C

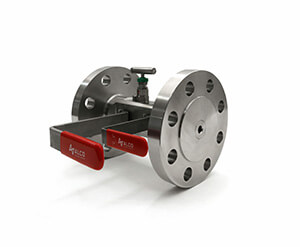

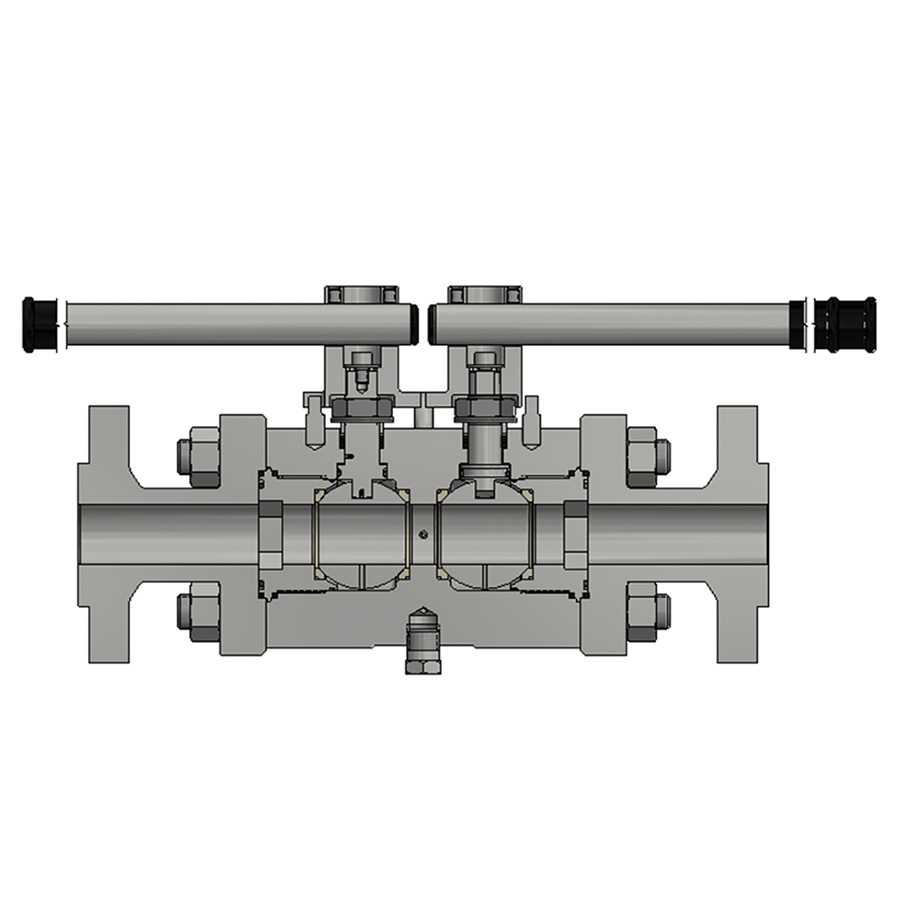

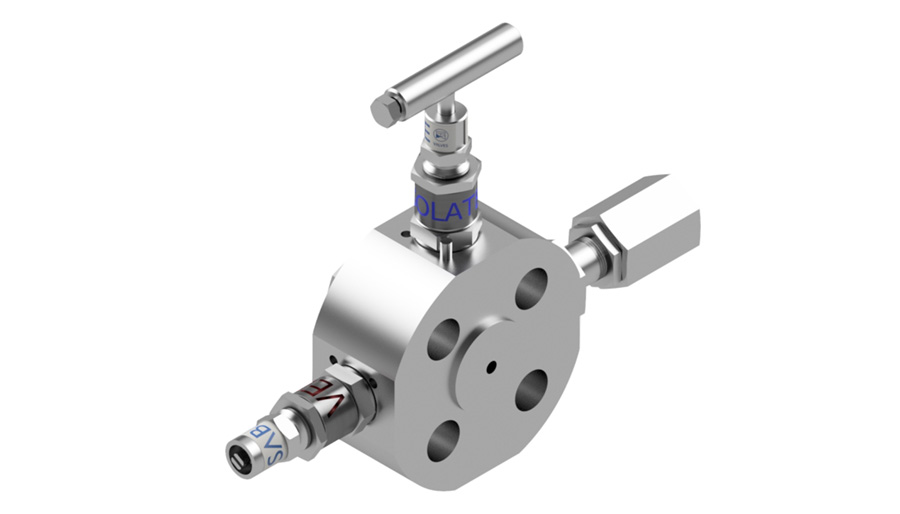

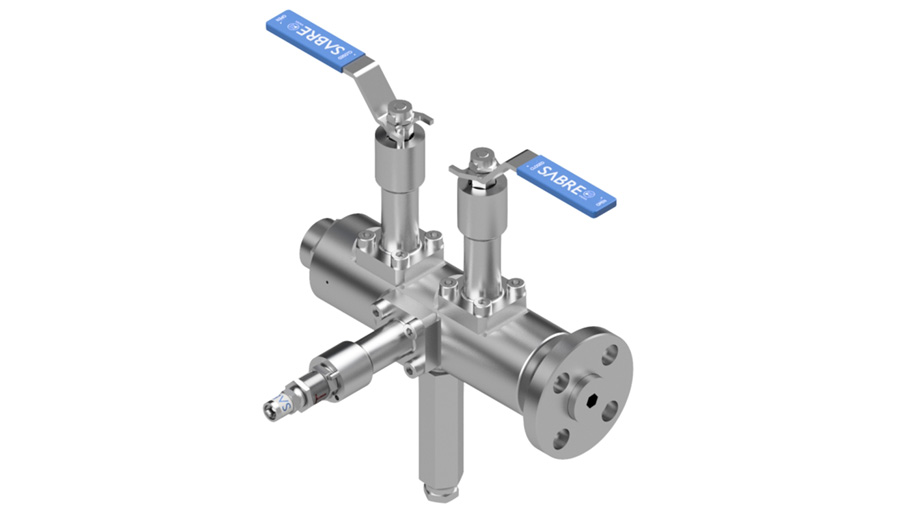

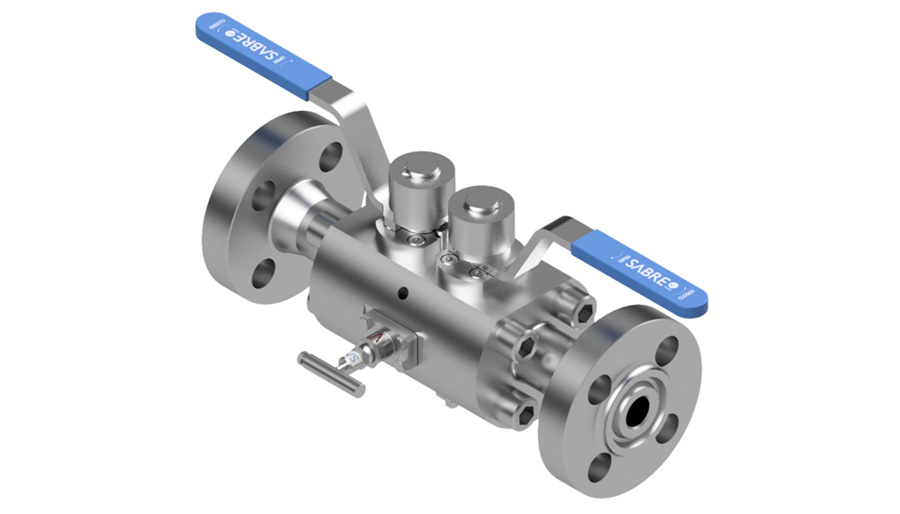

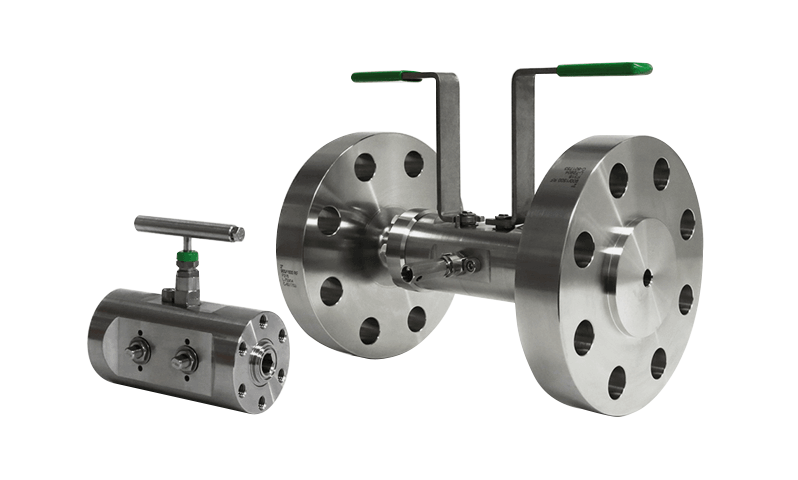

Single Isolate & Double block & bleed Specifications

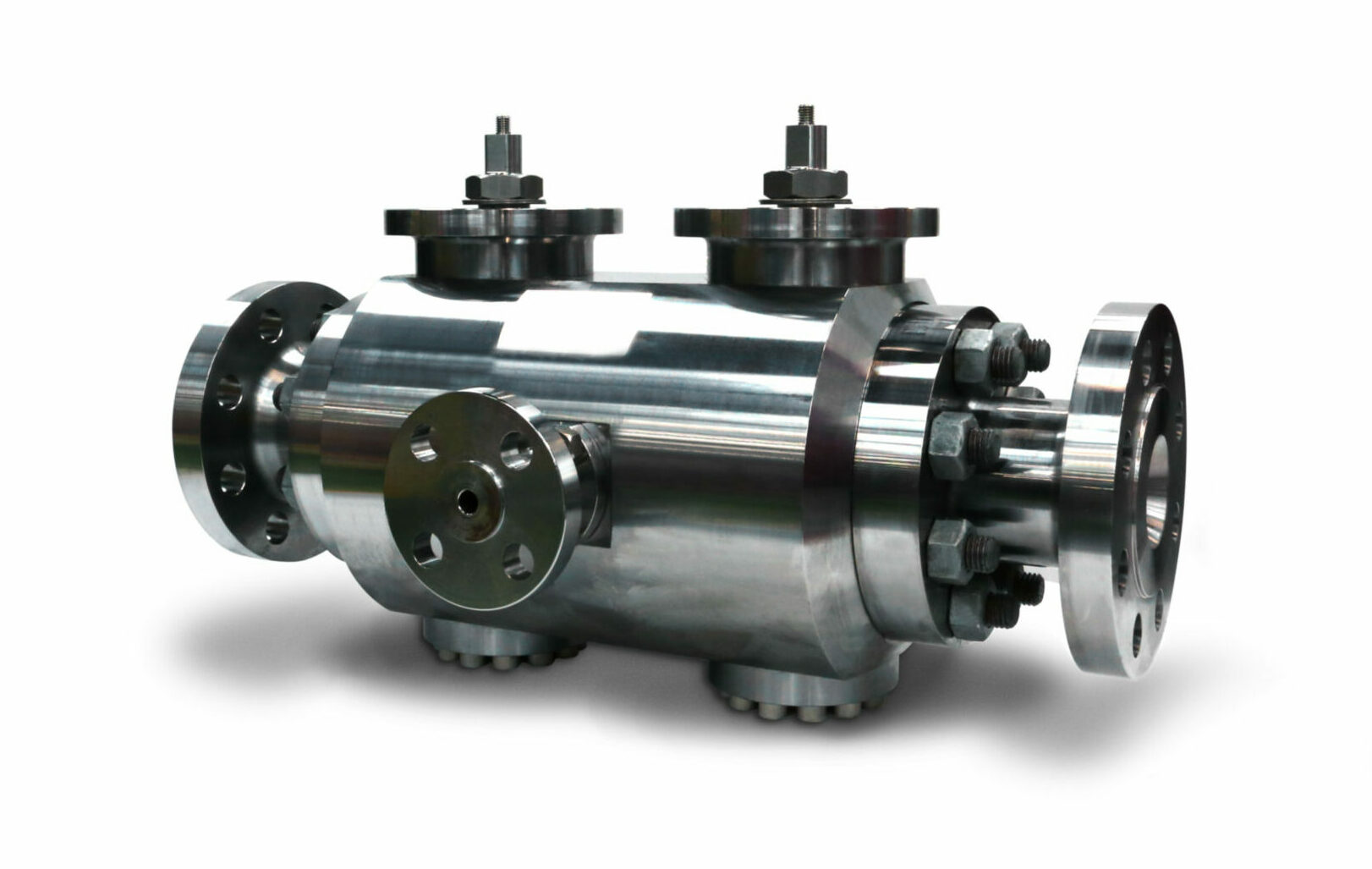

Type: Trunnion & Floating Balls

Size: 1/2″ to 12″ Full & Reduced Bore

Ratings: ASME Flanged 150lb To 2500lb, API 5, 10K & 15 K

Temp range: -46 To + 230 Deg C

Materials: Forged

Seats: Metal & Soft

Standards: ASME B16.34, ASME B16.5, ASME B16.10, API6D, API598, BS6755 PT2, API 6A, API 607, ISO15848-1&2, ATEX, PED

Contact us for More Information

If you would like to discuss our Hydrogen Valves, click the link below to get in touch with our Sales Team, who would be more than happy to answer all your questions.