01

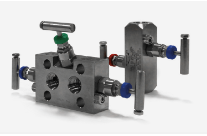

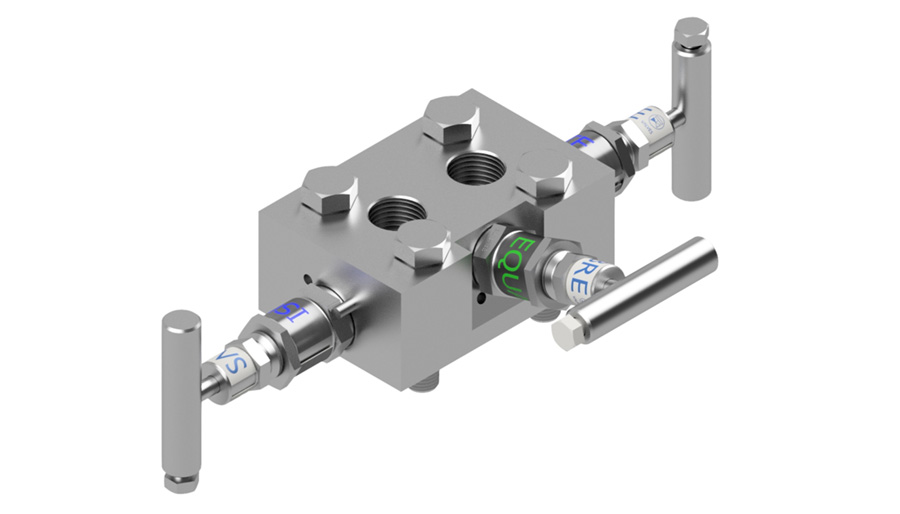

Overview

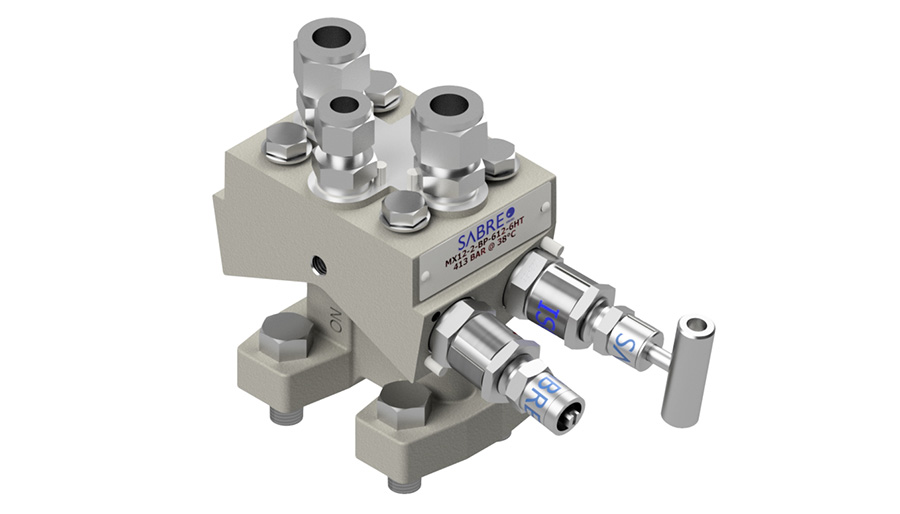

In the oil and gas sectors, reliability and safety are critical. That’s why we work hard to maintain our focus on quality assurance throughout all stages of the lifecycle of our products.

Our many approvals from leading oil and gas providers speak to the quality of our finished products and the services that support them. This quality would not be achieved without our focus on continuous improvement and management of change to ensure that our products meet or exceed customer expectations.

02

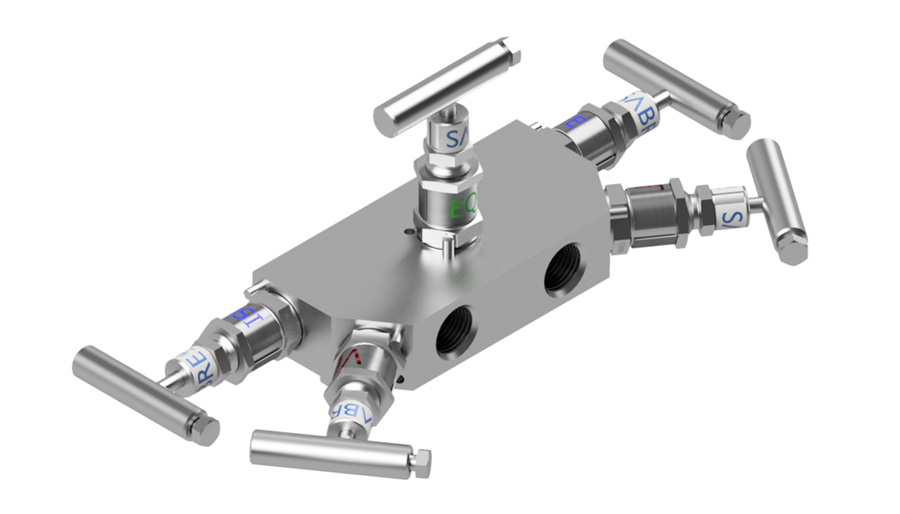

ACCREDITATIONS & CERTIFICATIONS

Our focus on quality management dates back many years – having held a BS5750 quality accreditation since 1982, we completed our ISO9001 accreditation in 2007. We also hold a number of industry specific accreditations, and many of our products have been assessed against stringent national and international qualification criteria in design codes such as ASME, API and ISO.

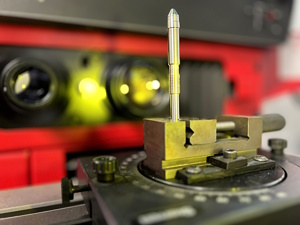

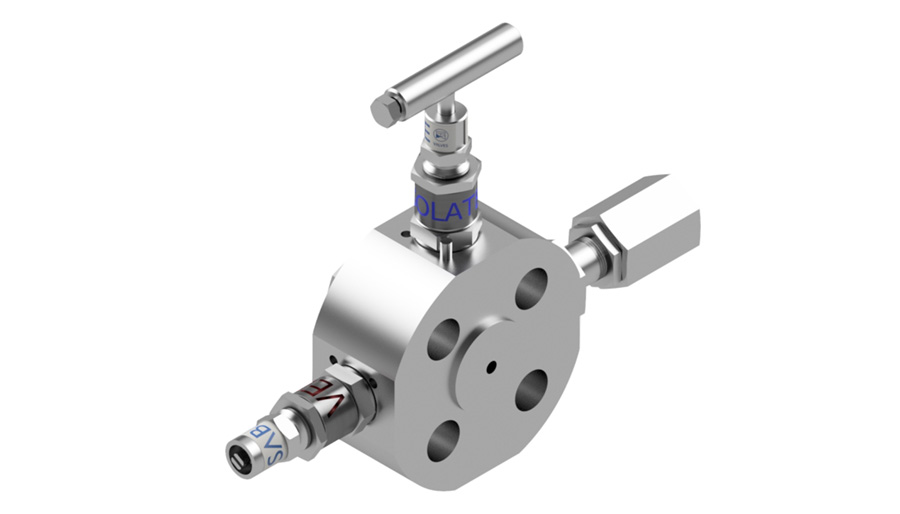

GOODS-IN INSPECTION

The quality process starts before the assembly and testing of products. We carry out thorough goods-in inspection ensuring all materials and finished components meet our requirements. Only then will they be used in a finished product that we put our name to.

OUR FOCUS ON PEOPLE

Our people are our greatest asset, and have been central to our growth. They also play a vital role in our quality assurance processes. We involve staff at all levels of the business to ensure that we have a clear focus and a succession plan for the future. Quality is principal to everything we do as a business.

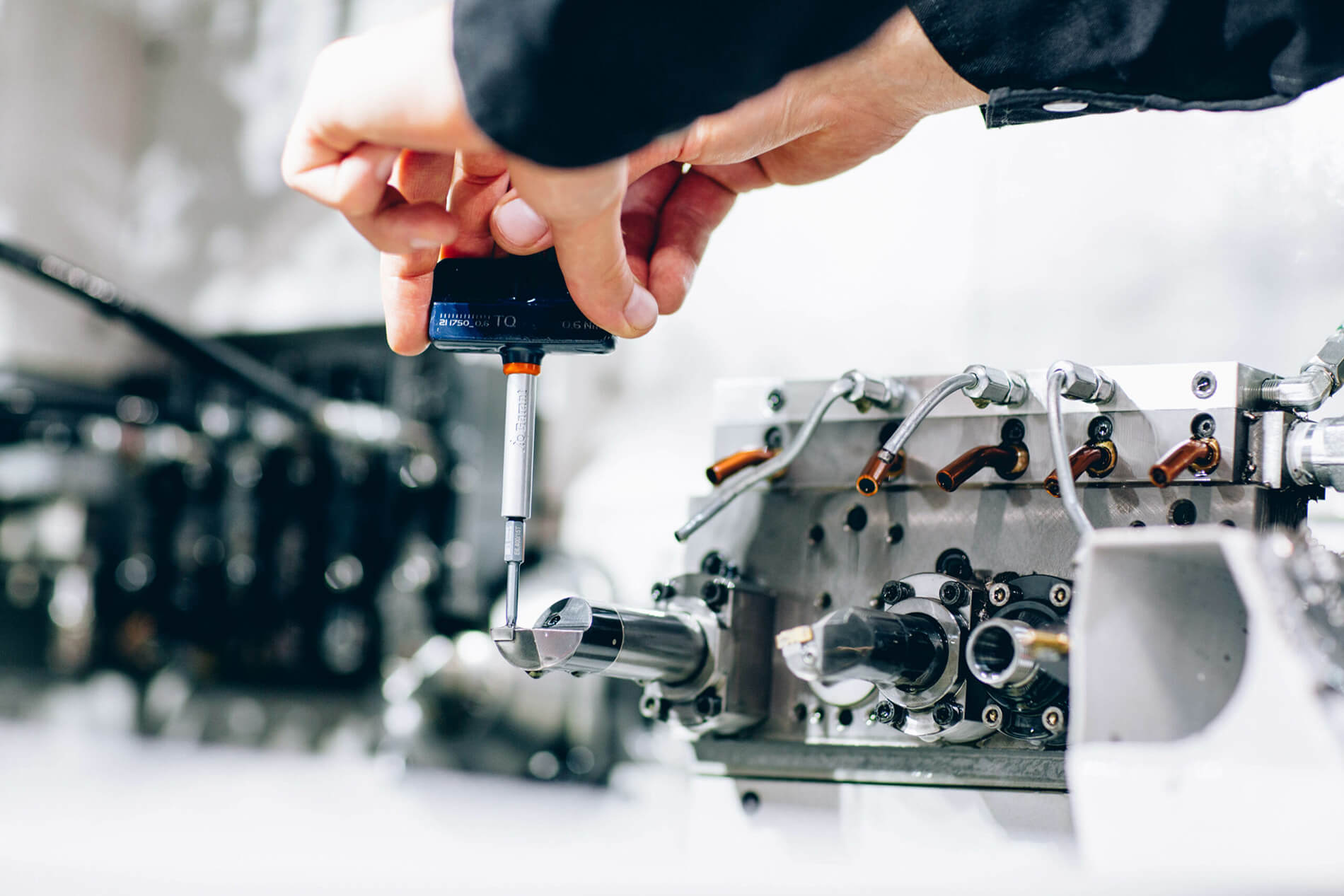

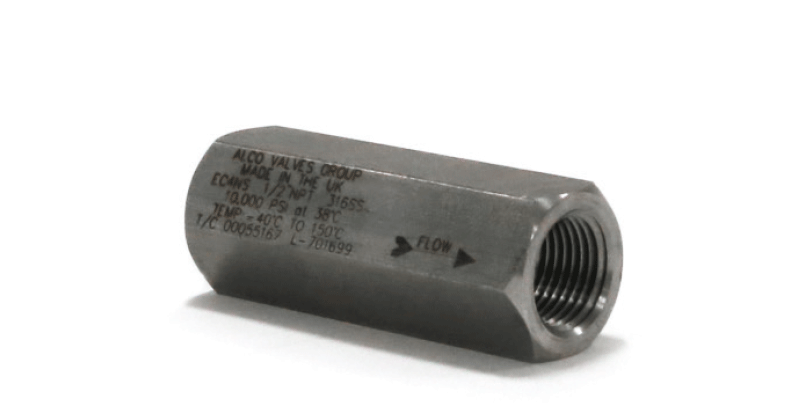

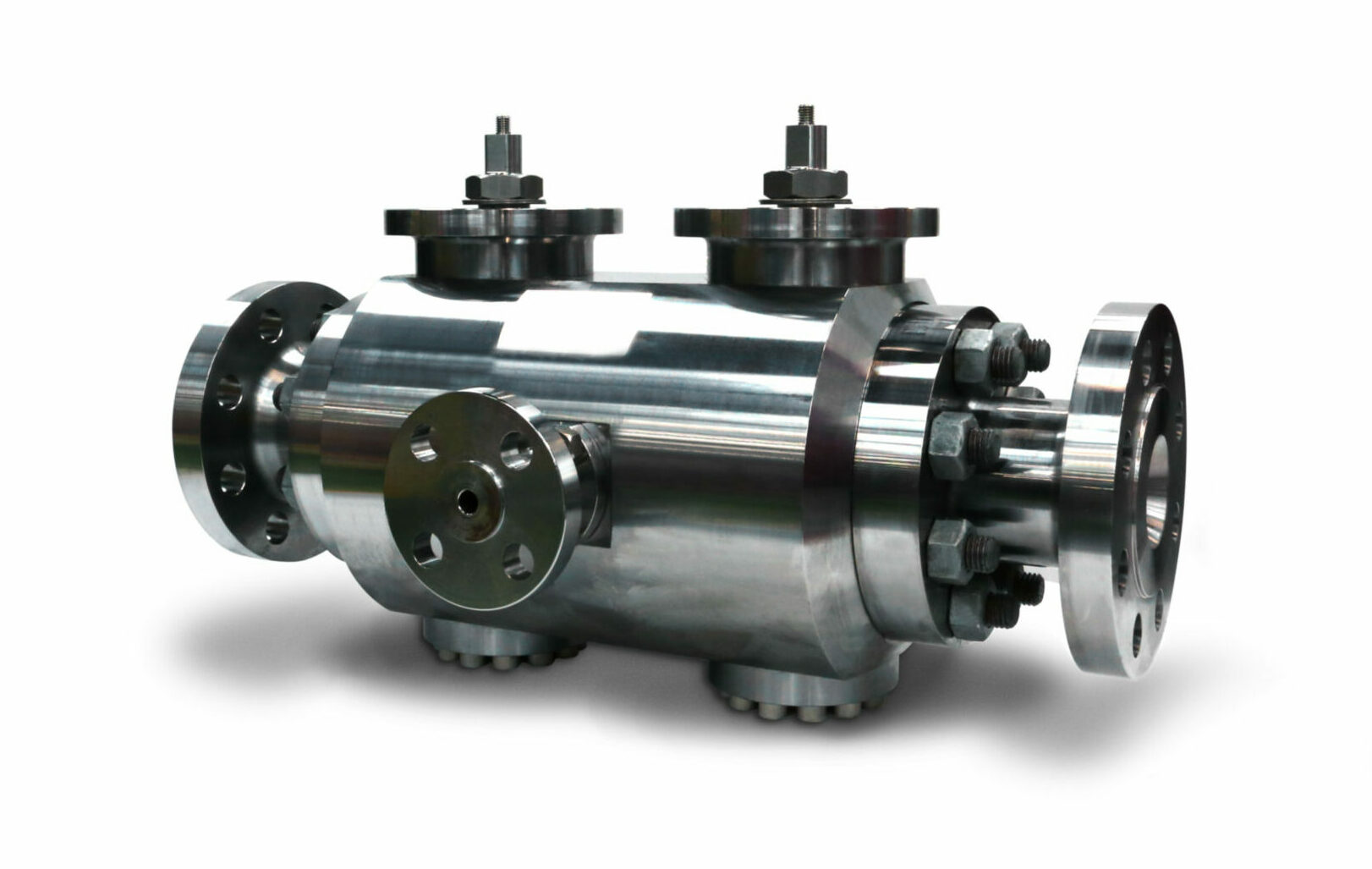

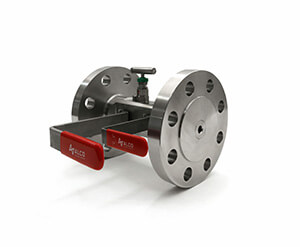

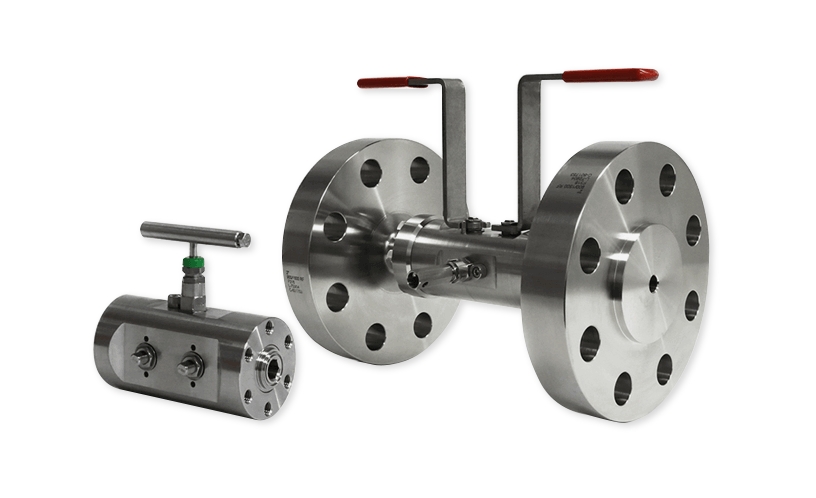

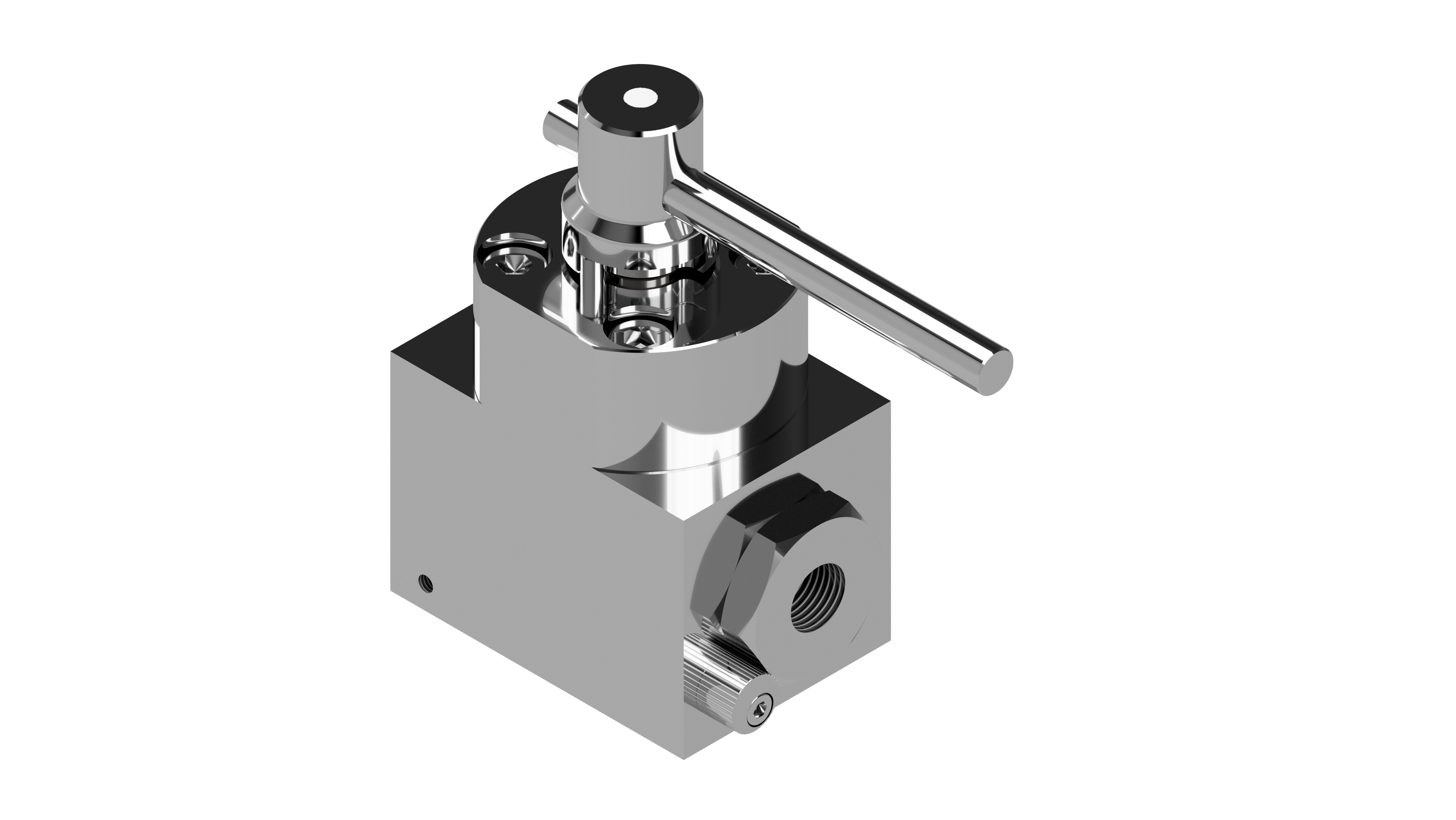

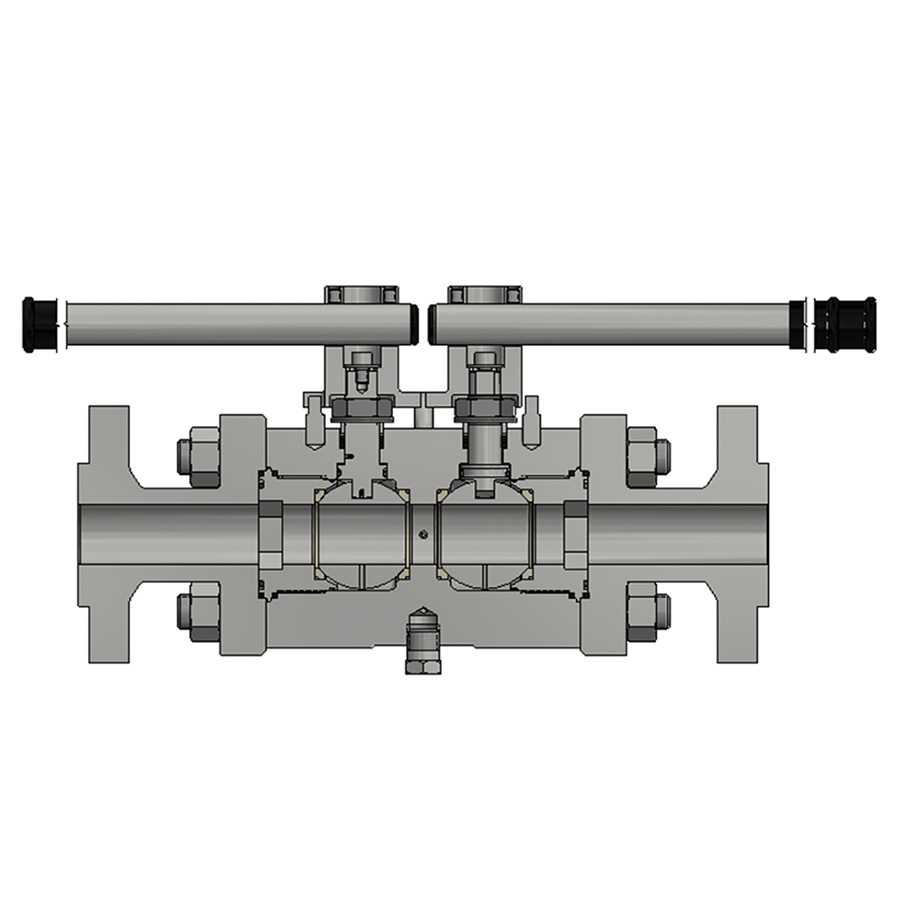

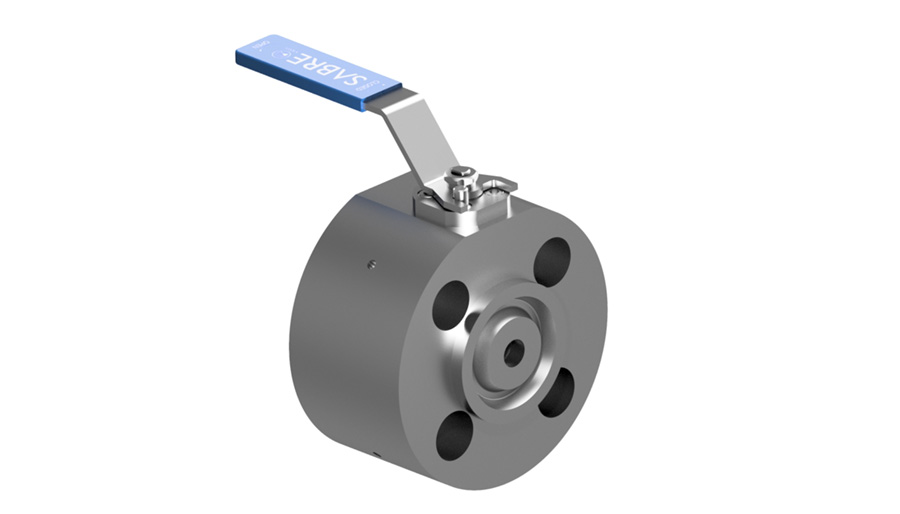

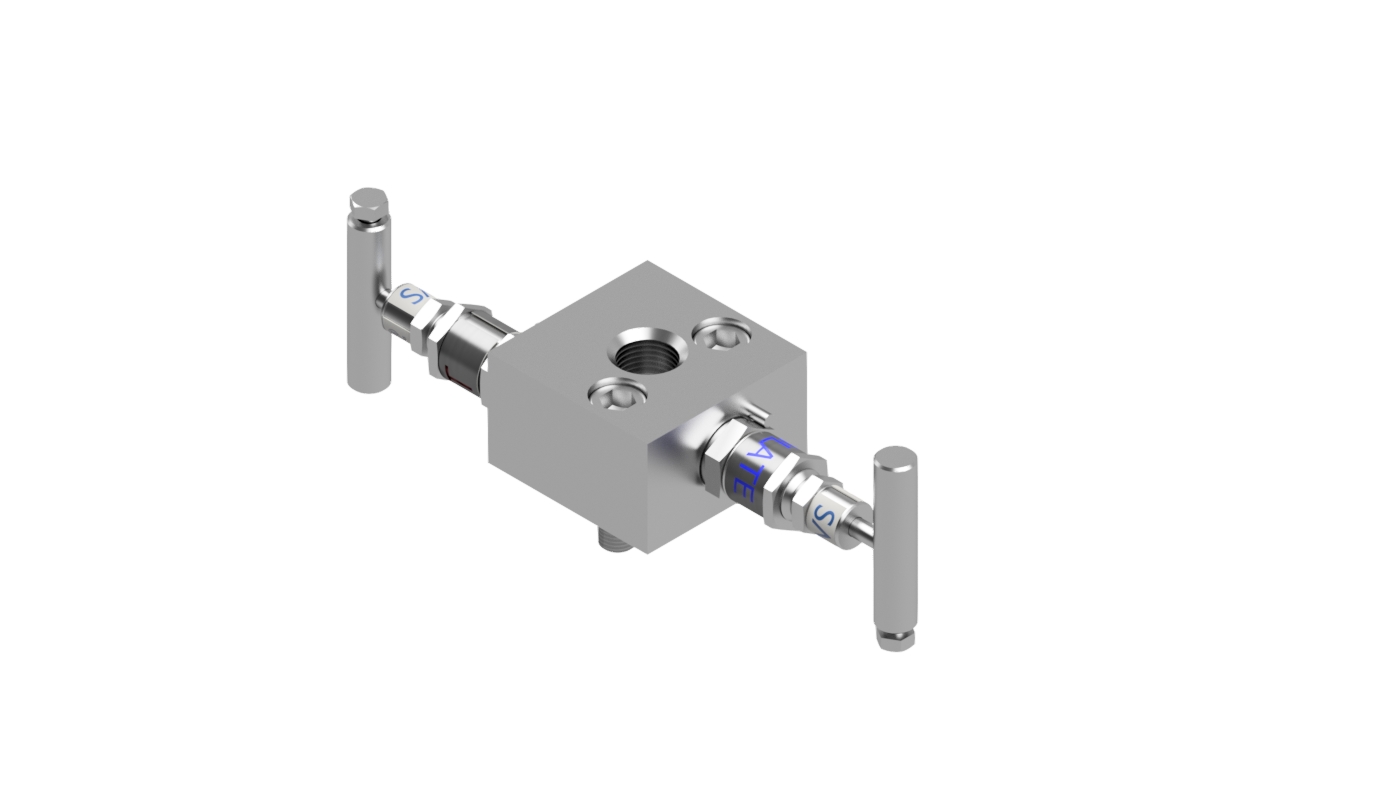

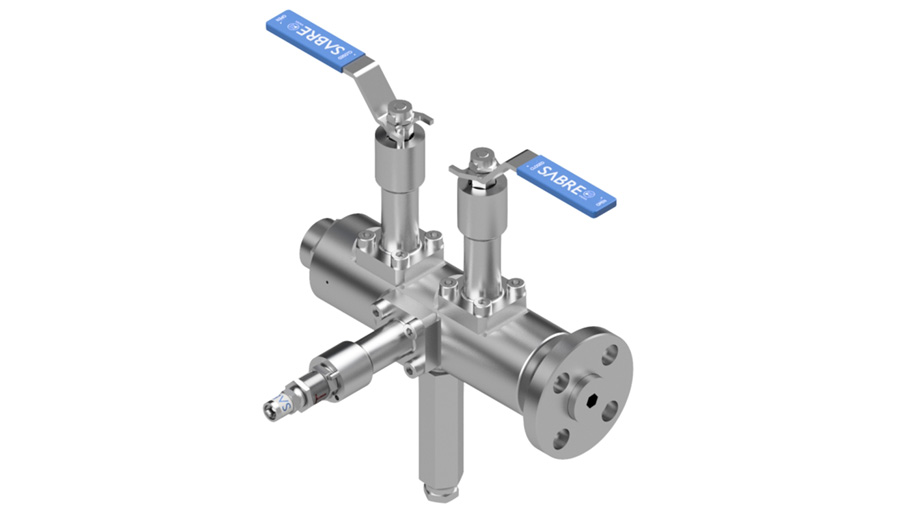

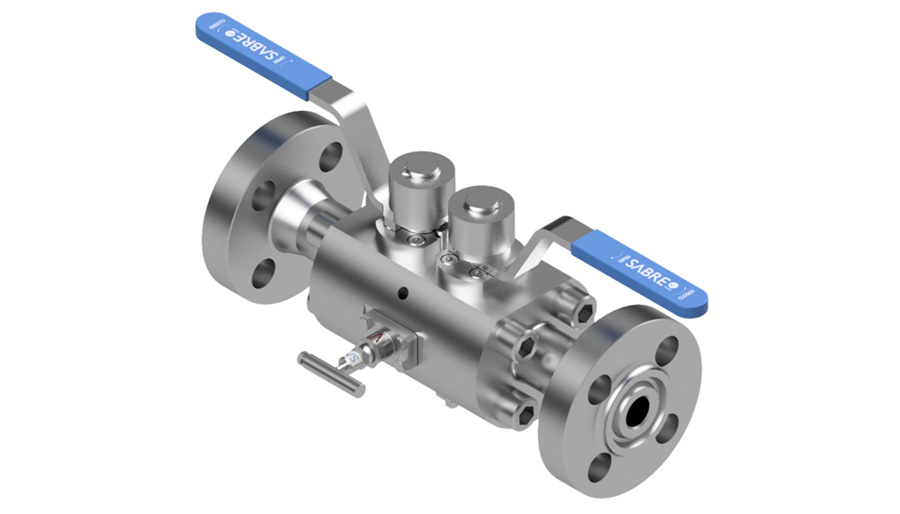

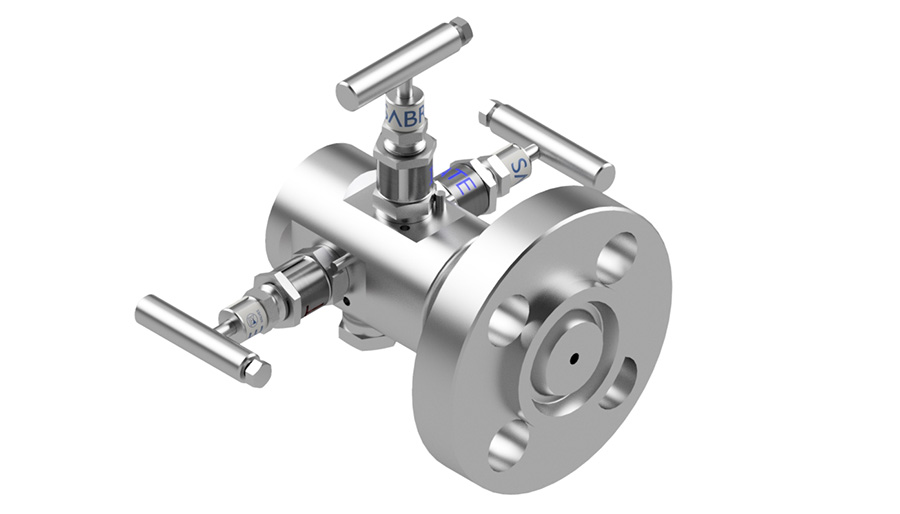

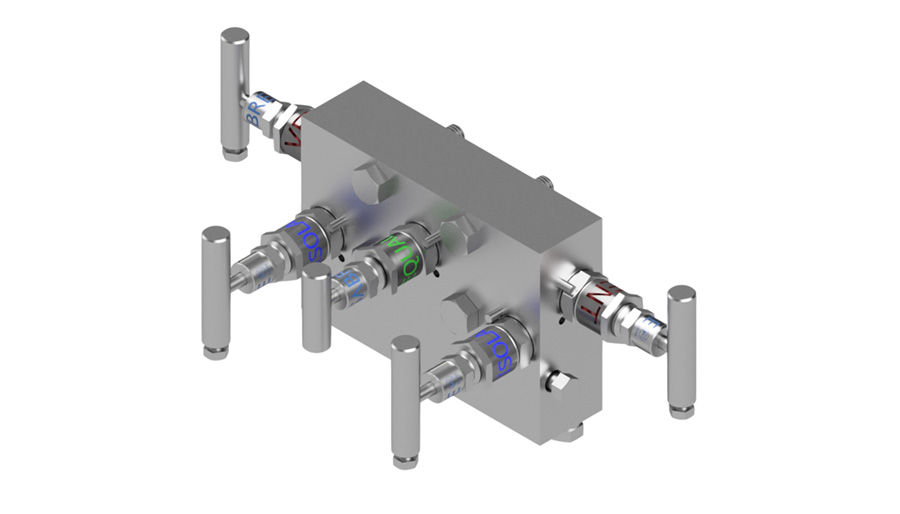

PRODUCT TESTING

All finished products are tested thoroughly on-site in accordance with the requirements of the design code and client specifications. Specialised test rigs and procedures have been developed to ensure every valve meets these requirements before it leaves the factory to begin a lifetime in service.