- Home

- Companies

-

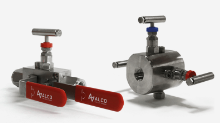

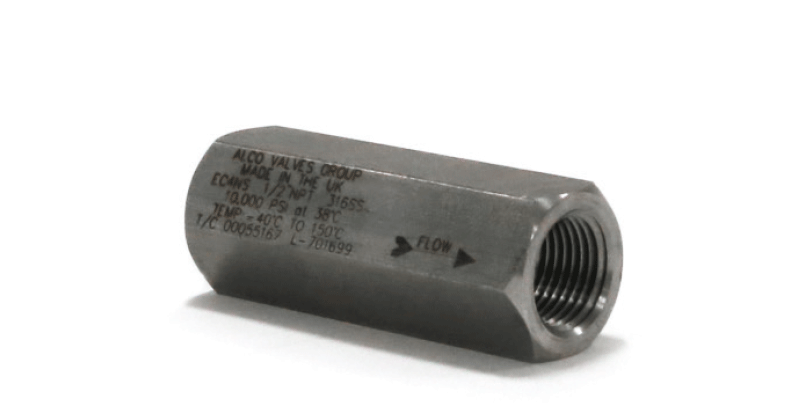

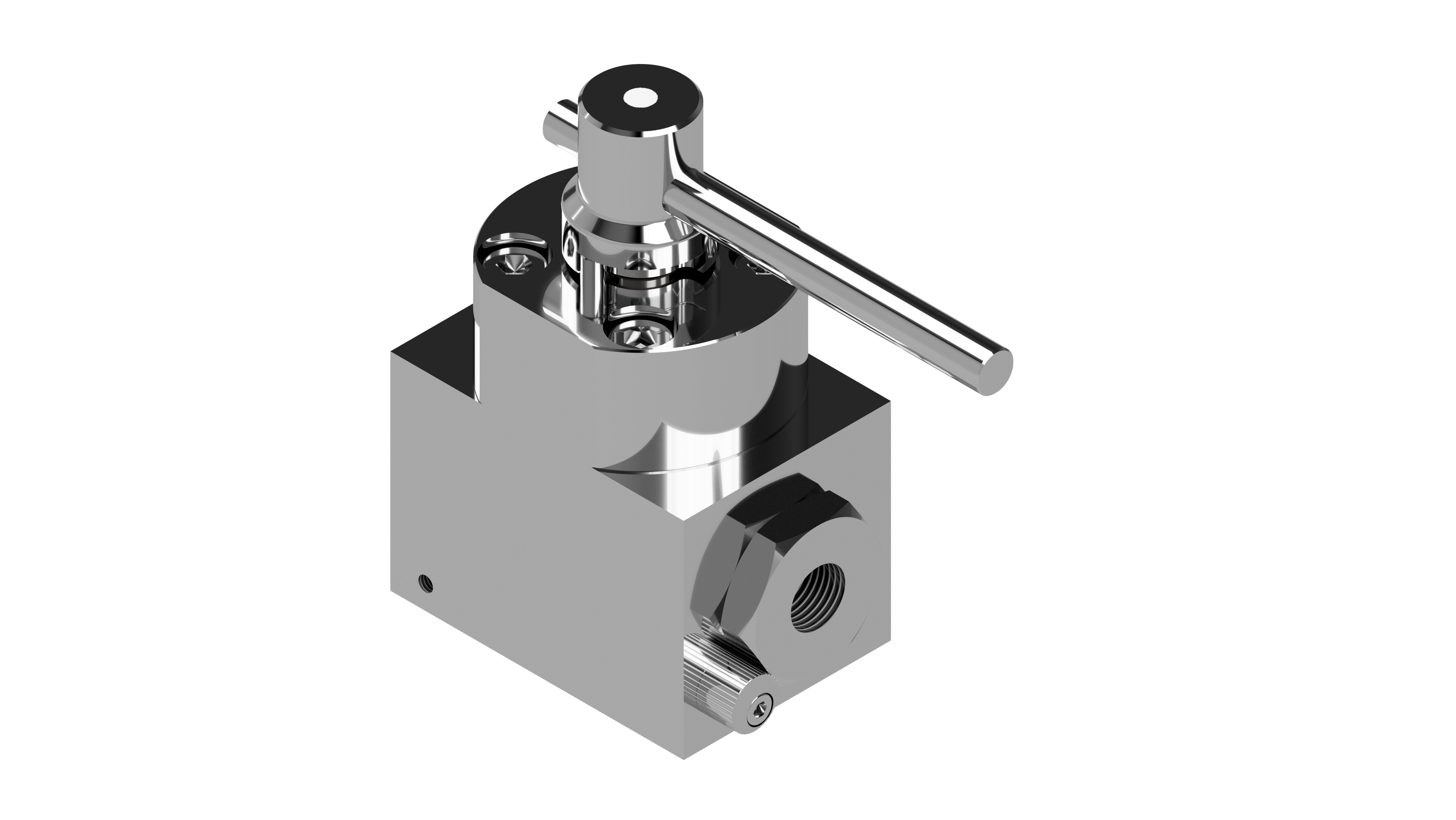

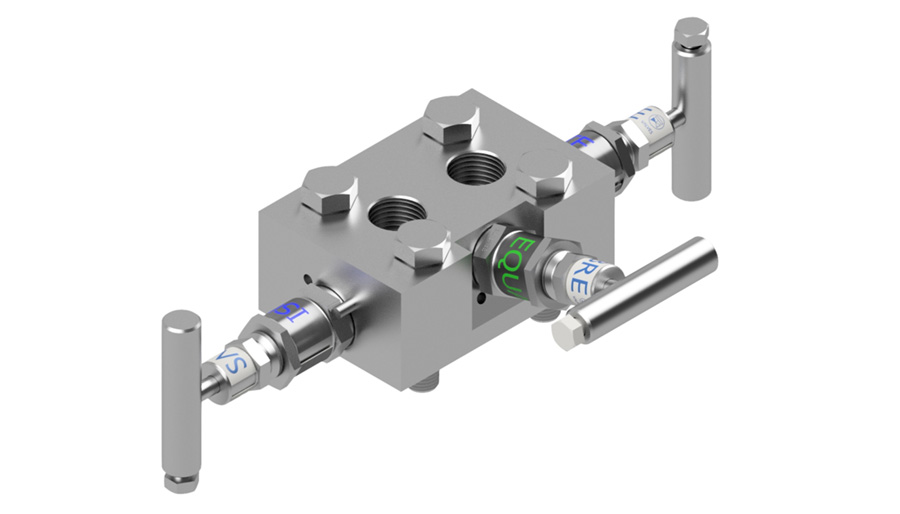

Alco Valves

- INSTRUMENTATION VALVES

- Ready to Go (RTG)

- Hydrogen Valves

- INSTRUMENTATION VALVES

- Ready to Go (RTG)

- Hydrogen Valves

-

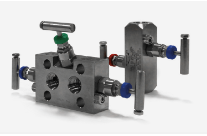

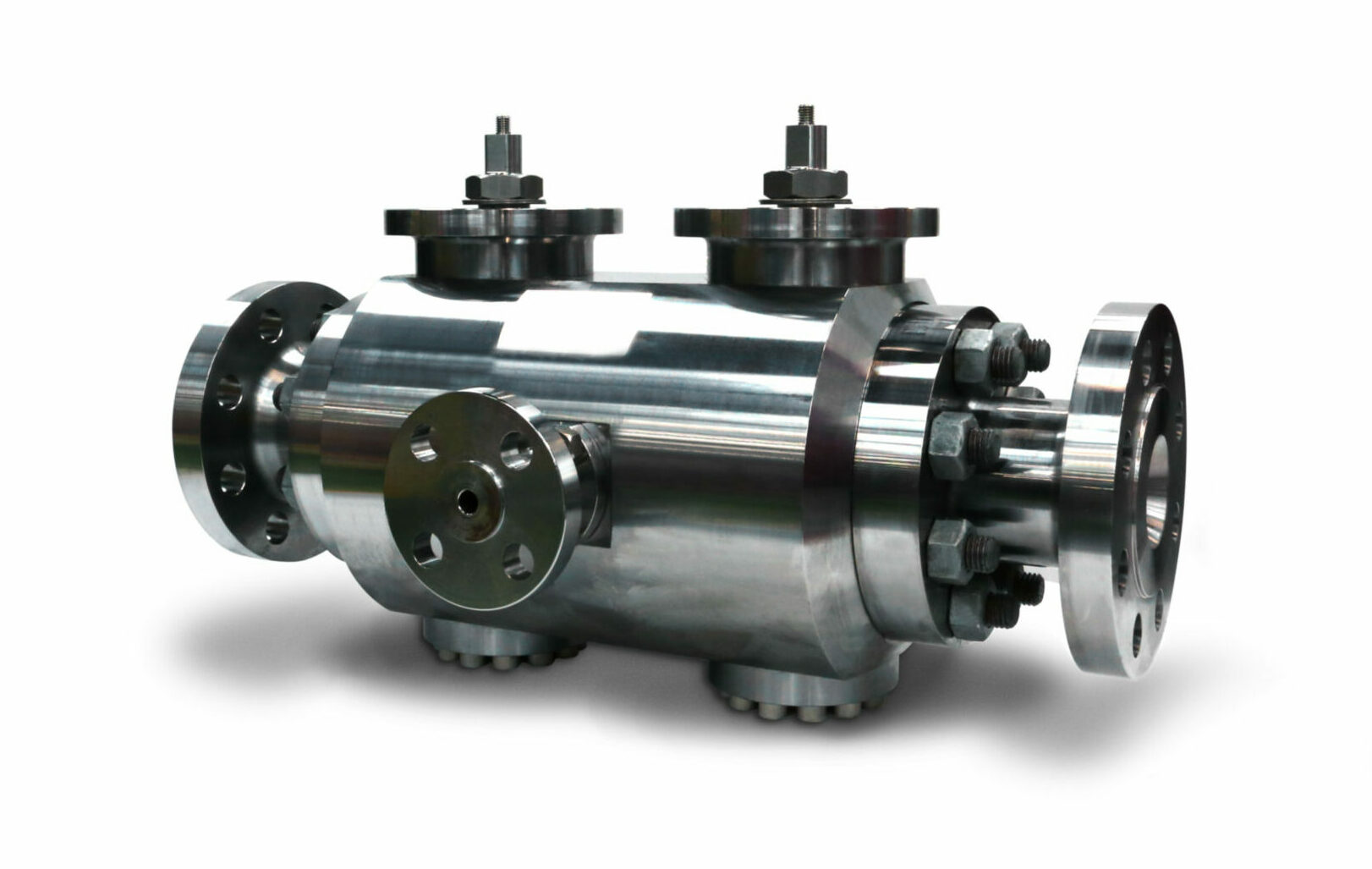

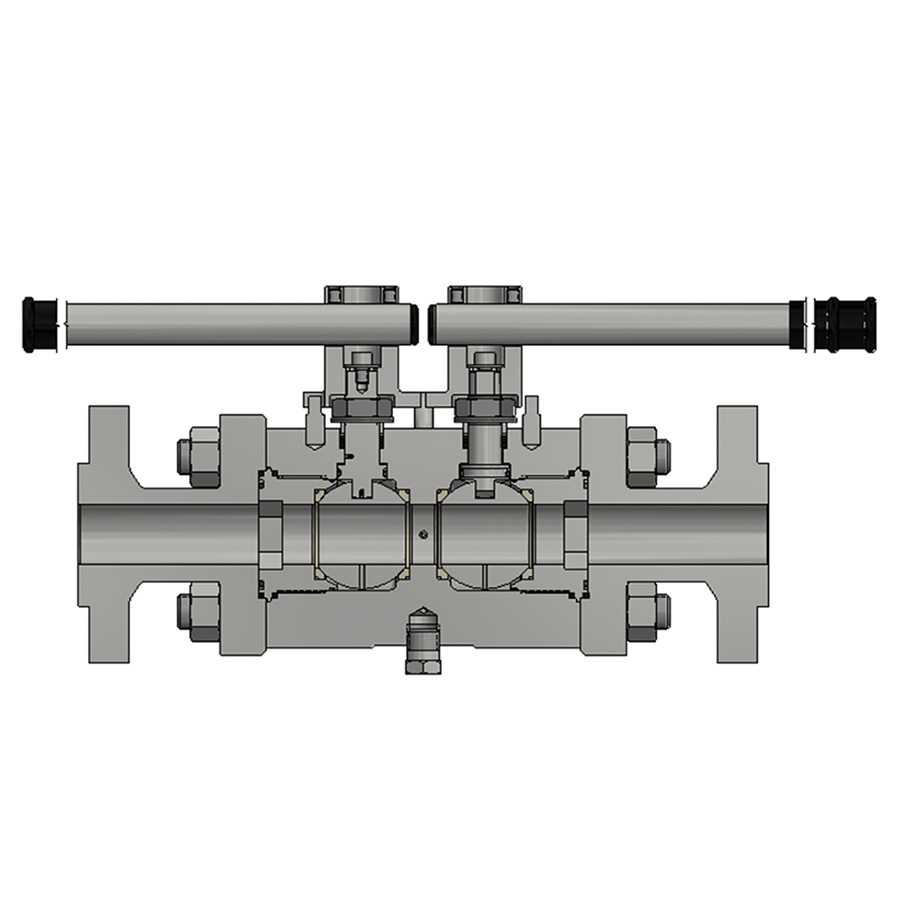

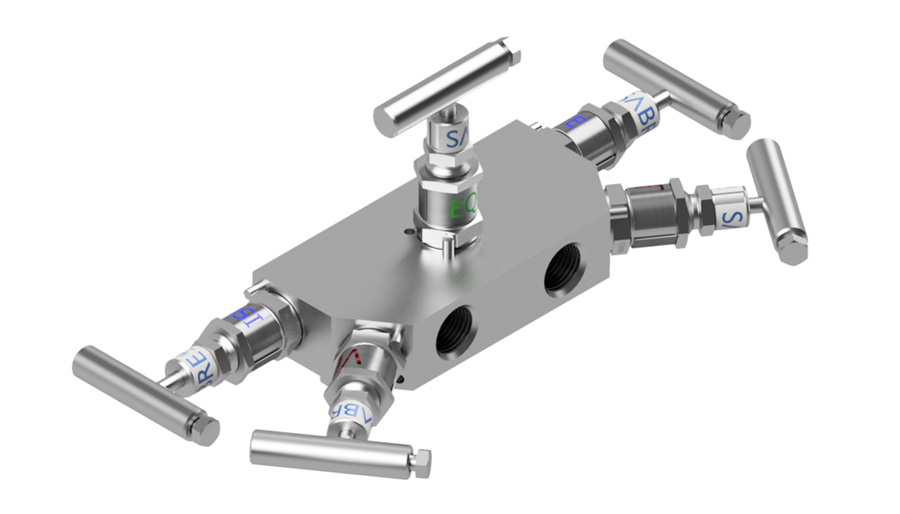

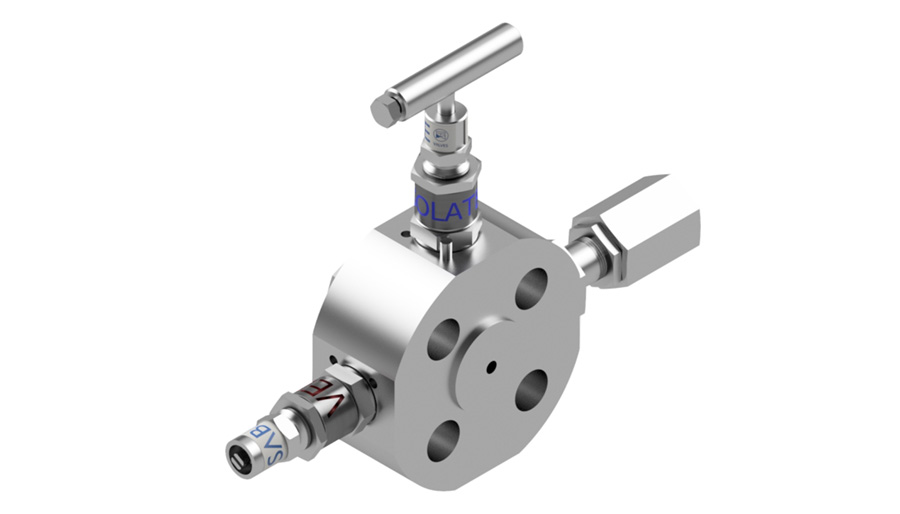

HI-TEK Valves

- Double Block and Bleed Valves

- Subsea

- Hydrogen Valves

- Double Block and Bleed Valves

- Subsea

- Hydrogen Valves

-

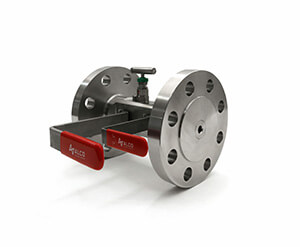

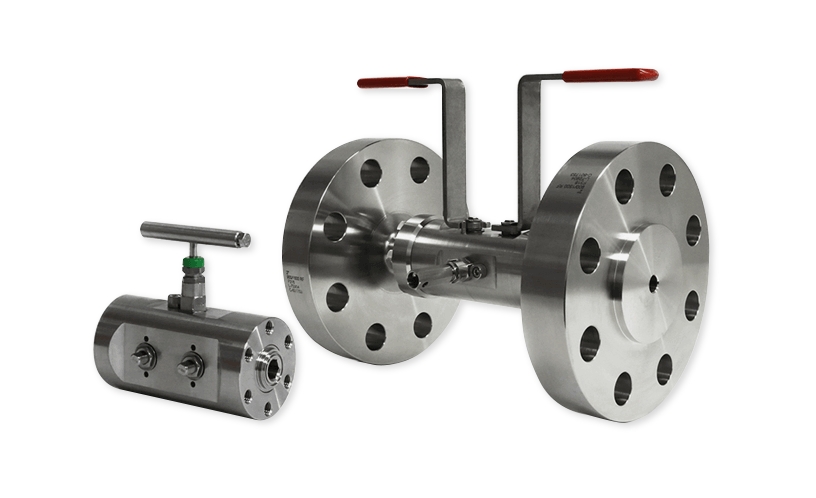

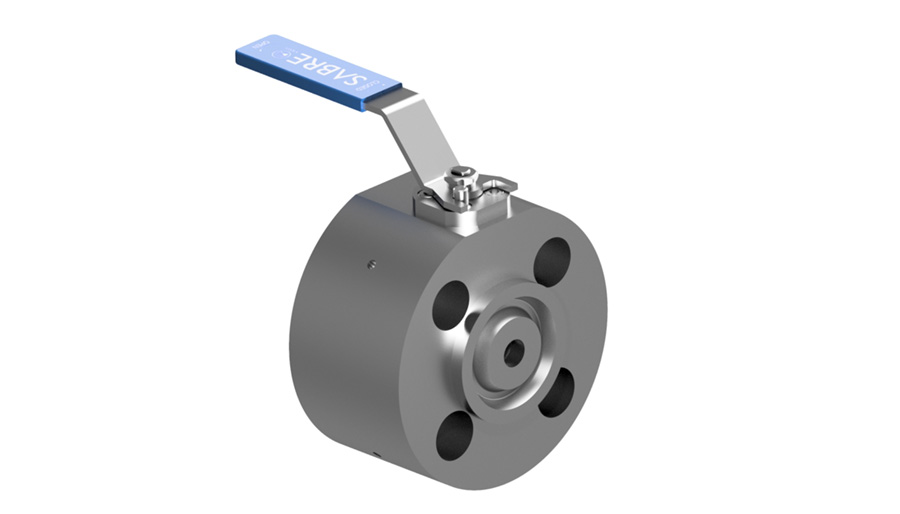

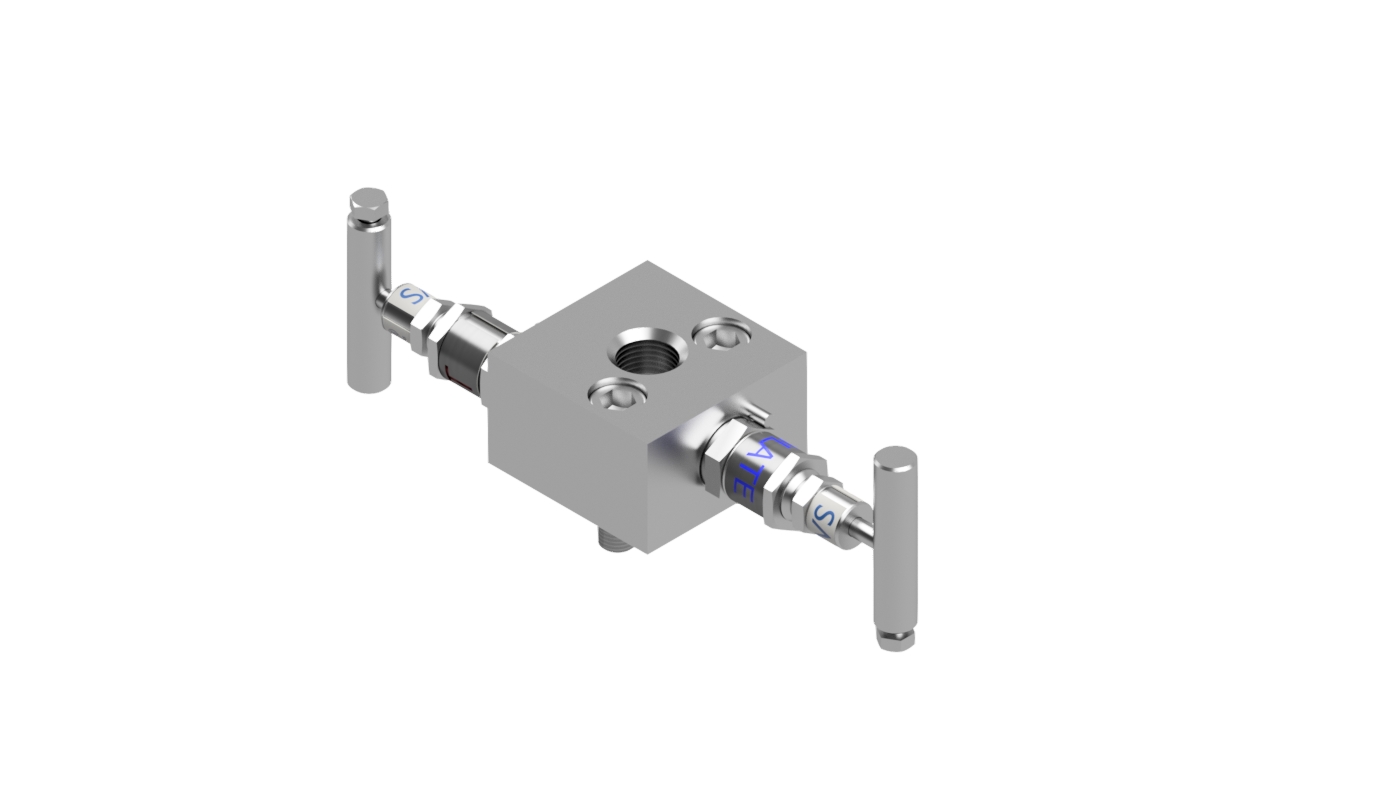

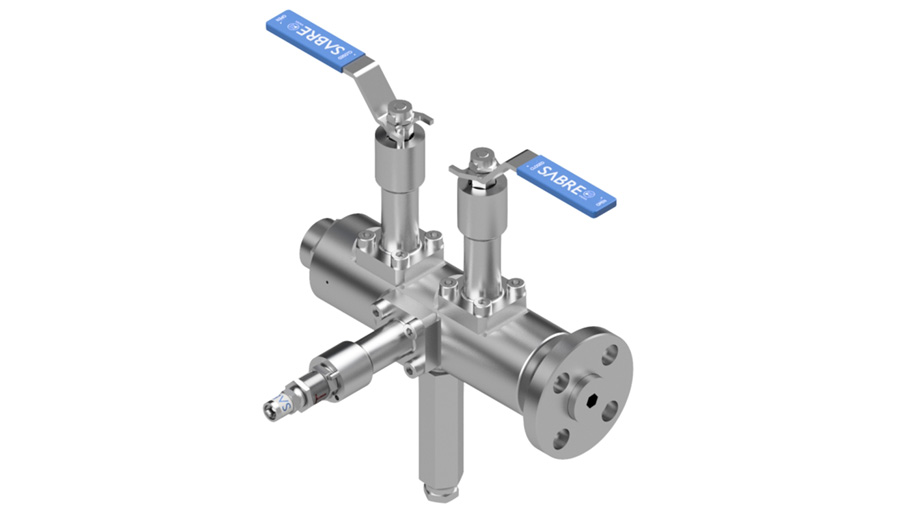

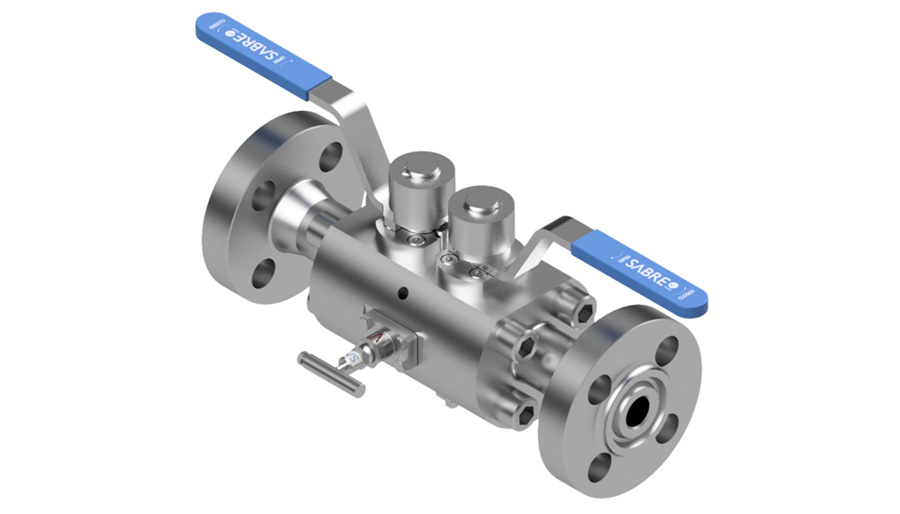

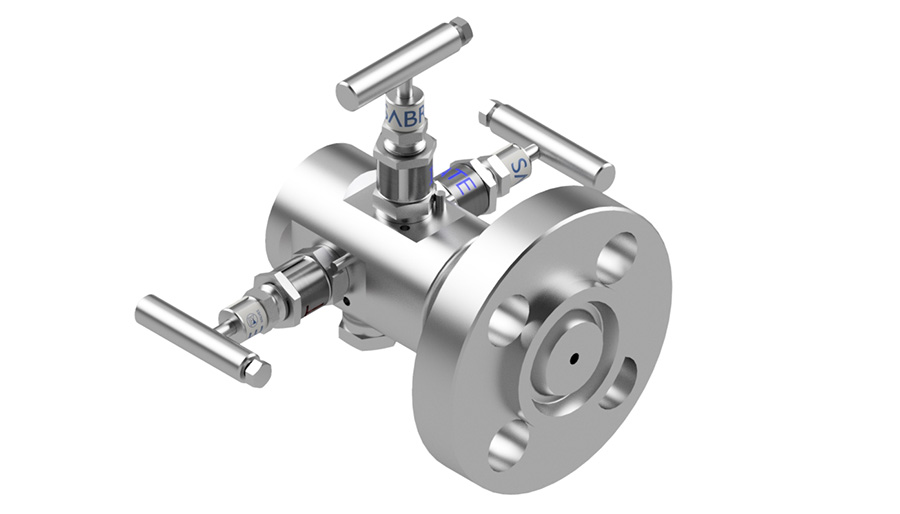

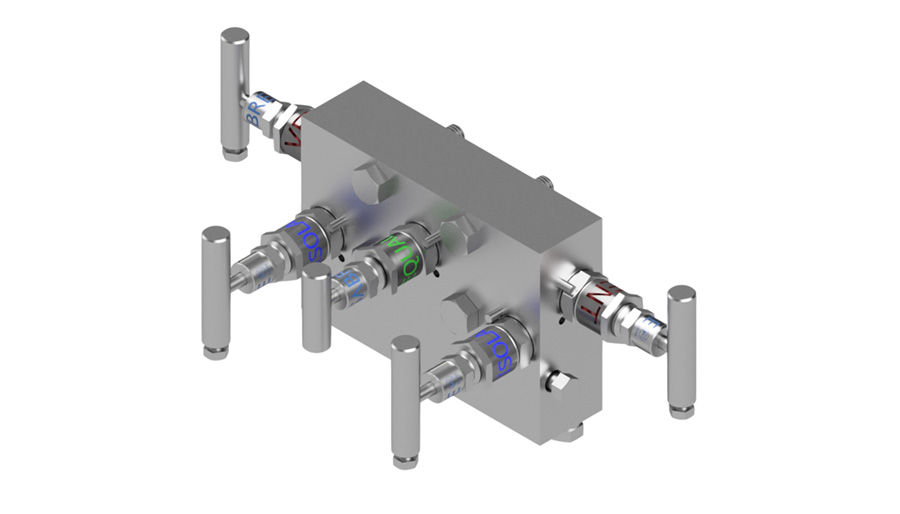

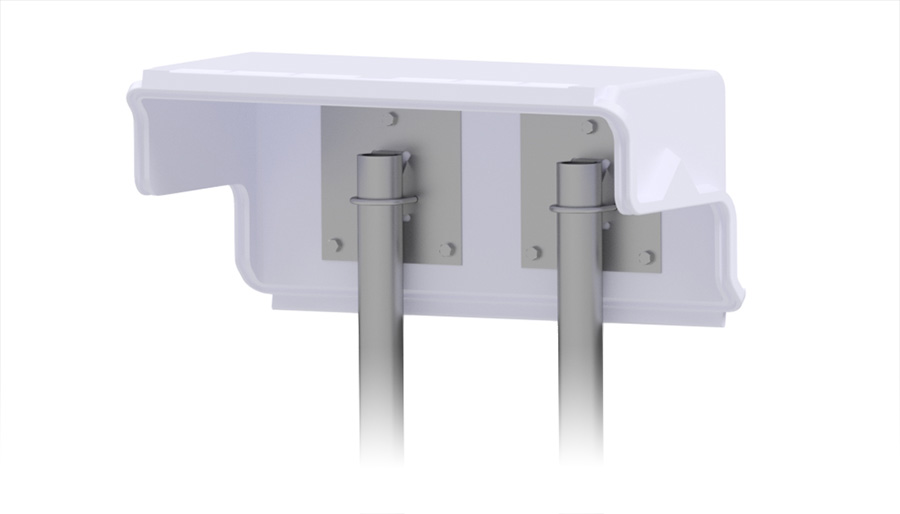

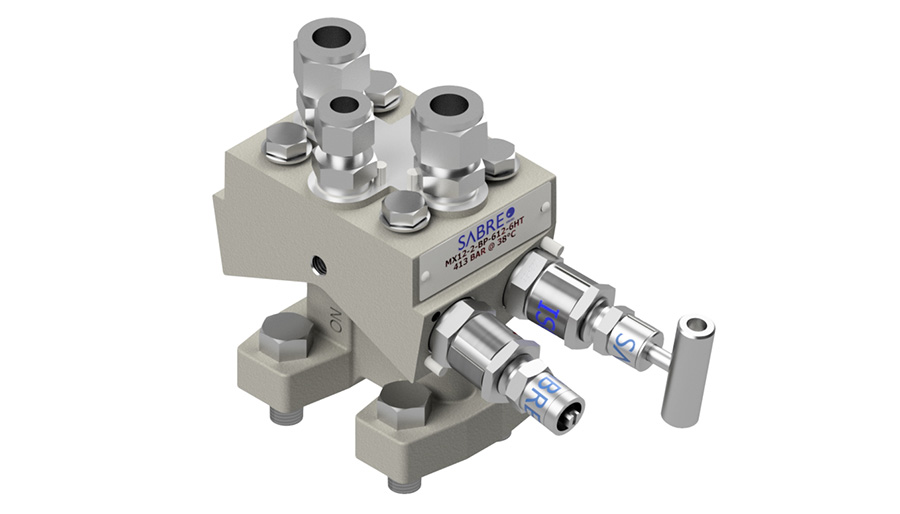

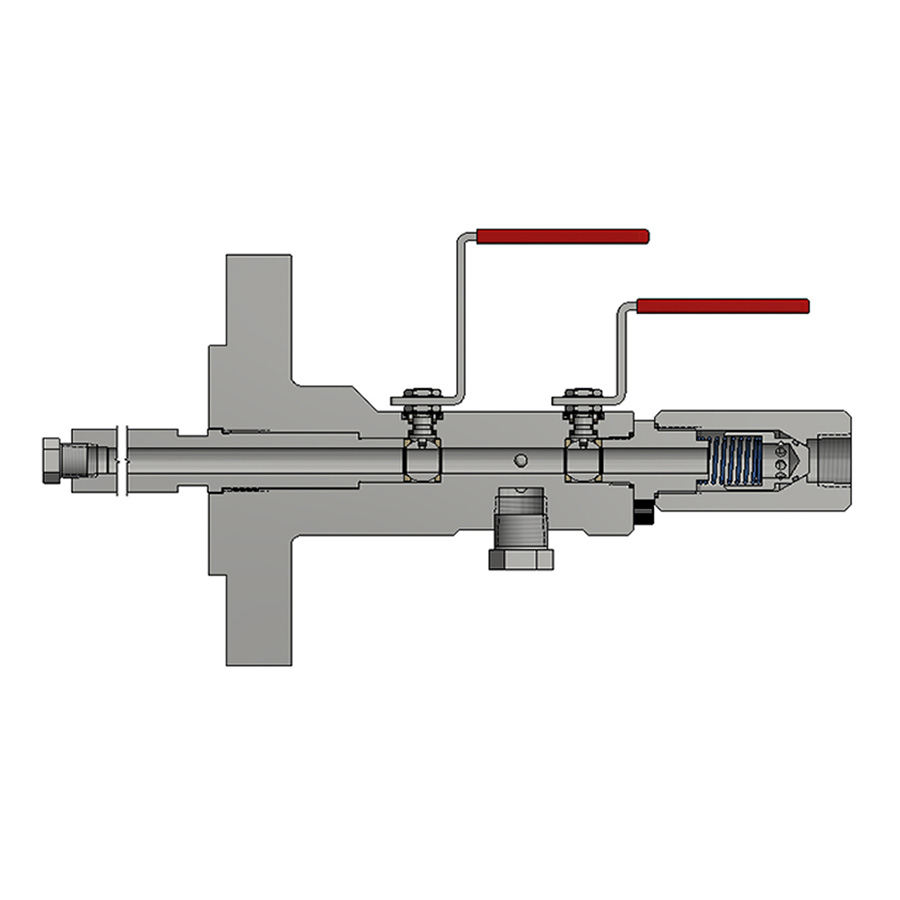

Sabre Valves

- Instrument Valves

- DBB Valves

- Hydrogen Valves

- Enclosures

- Instrument Systems

- Instrument Valves

- DBB Valves

- Hydrogen Valves

- Enclosures

- Instrument Systems