COMPANY

MANUFACTURING + TESTING

Manufacturing Accreditations

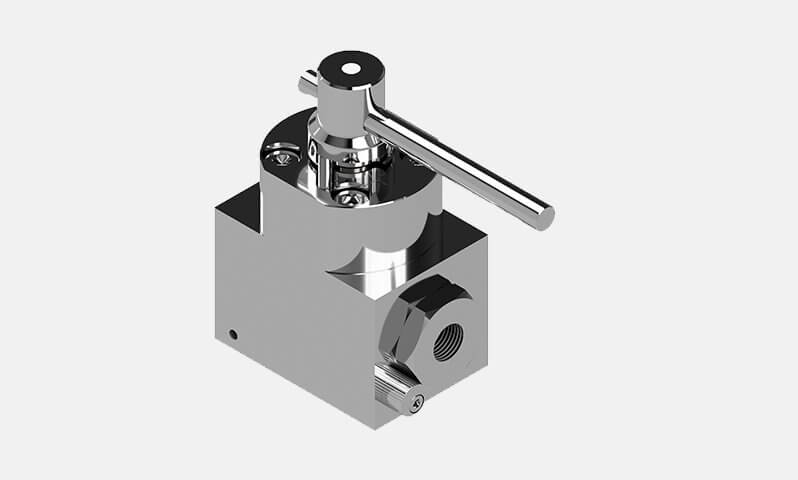

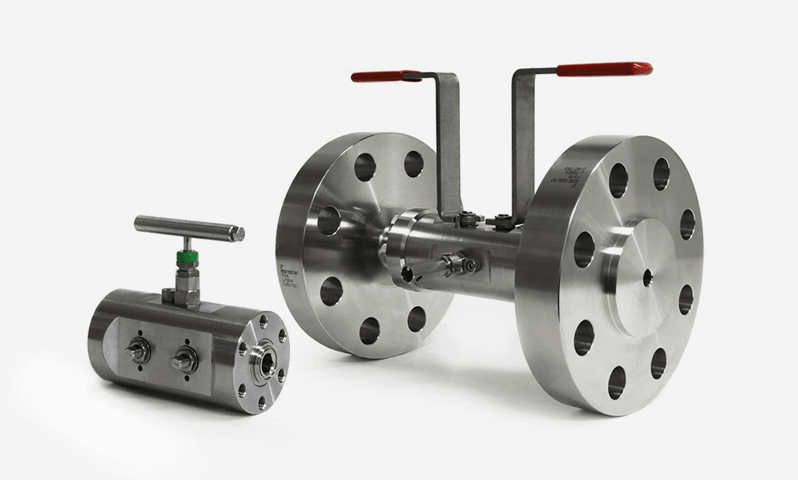

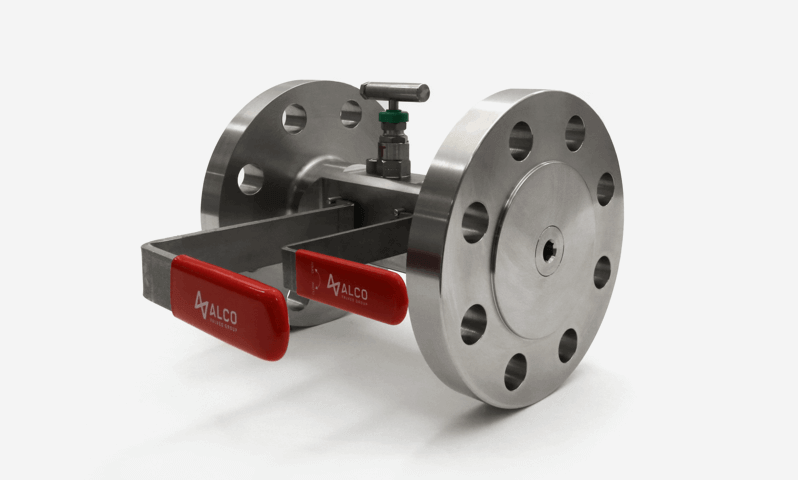

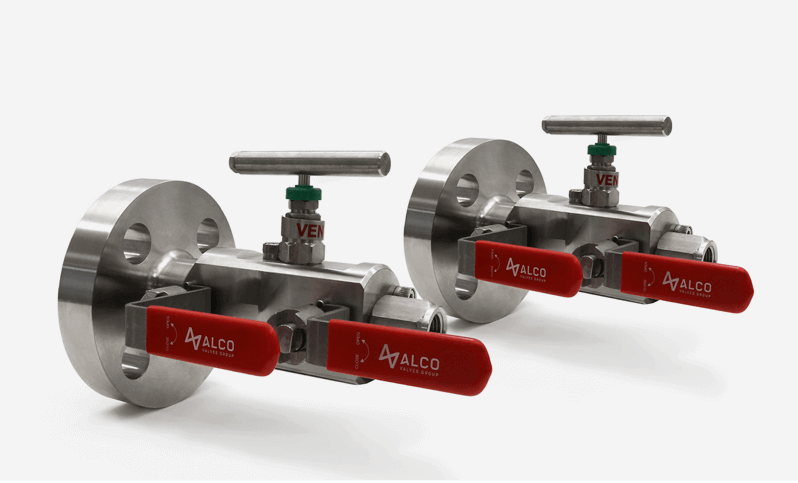

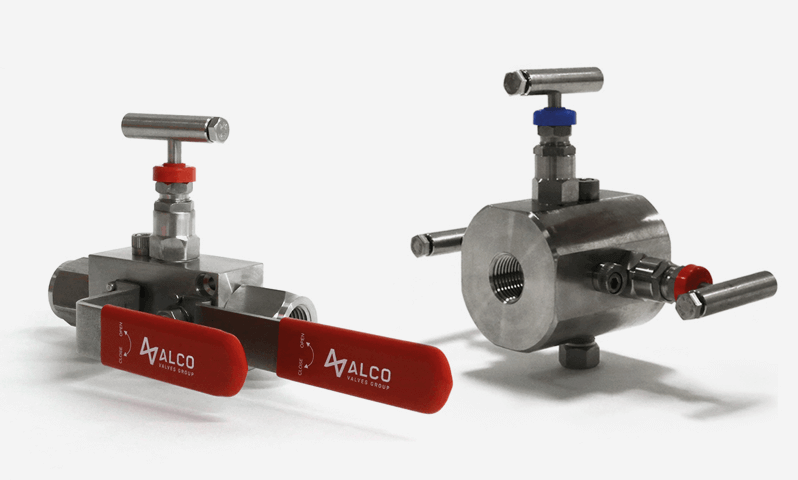

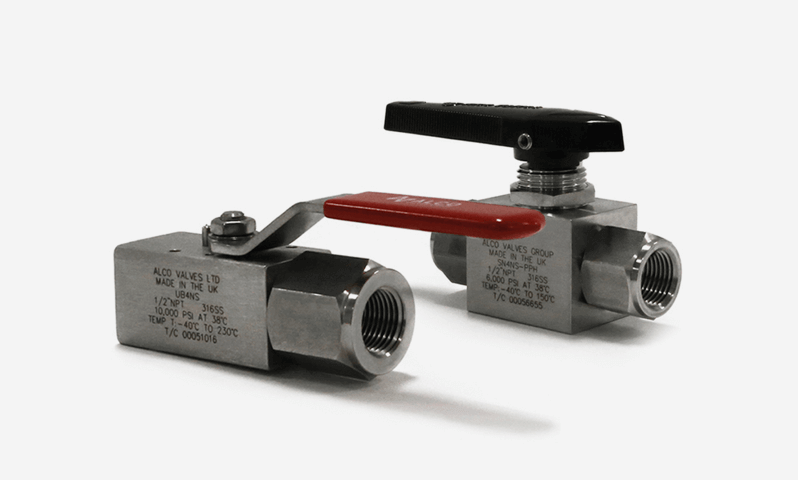

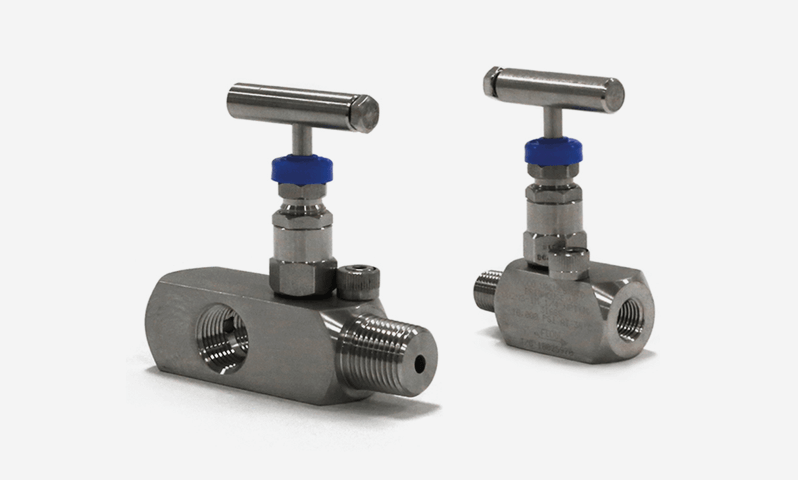

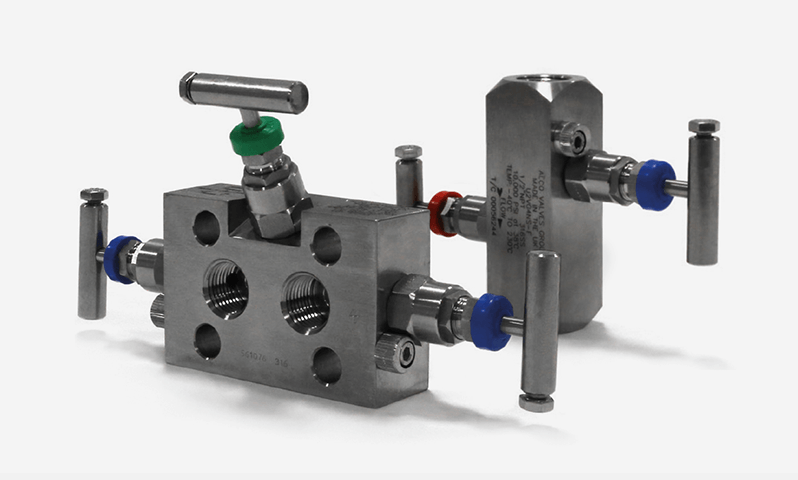

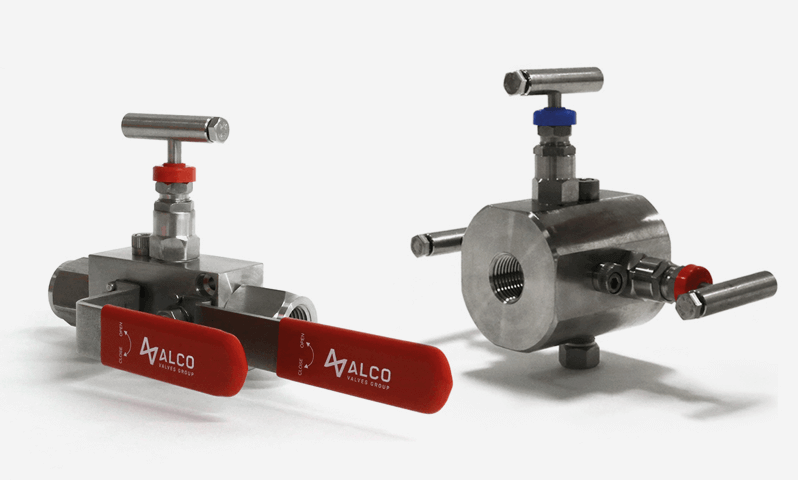

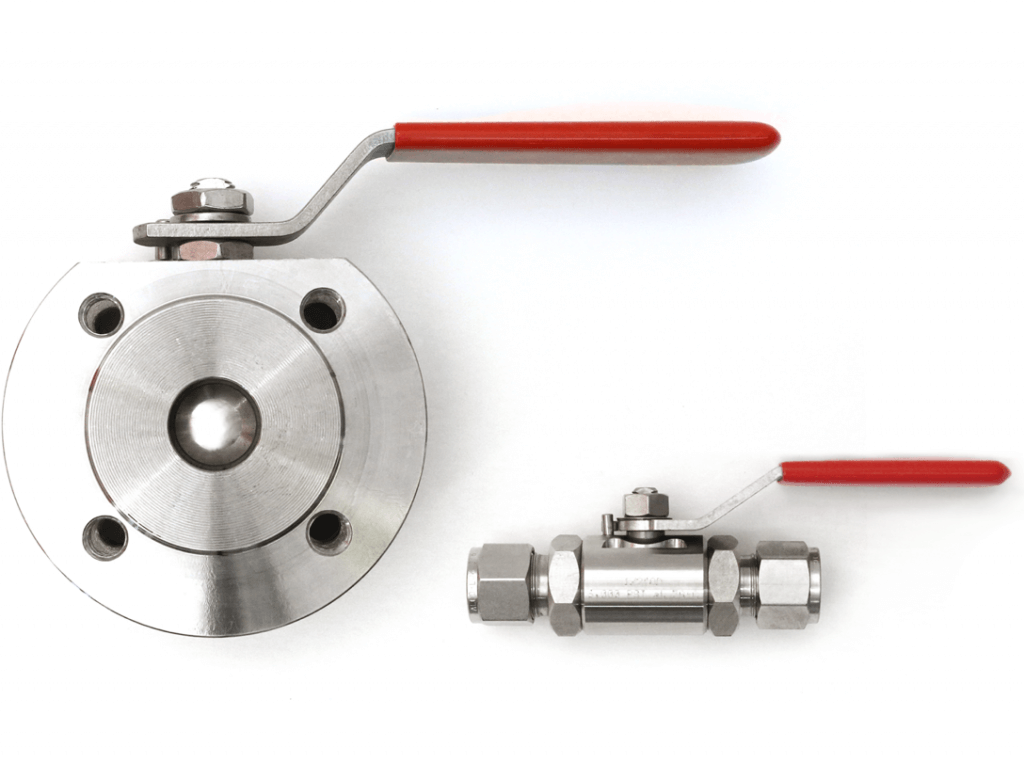

Overview

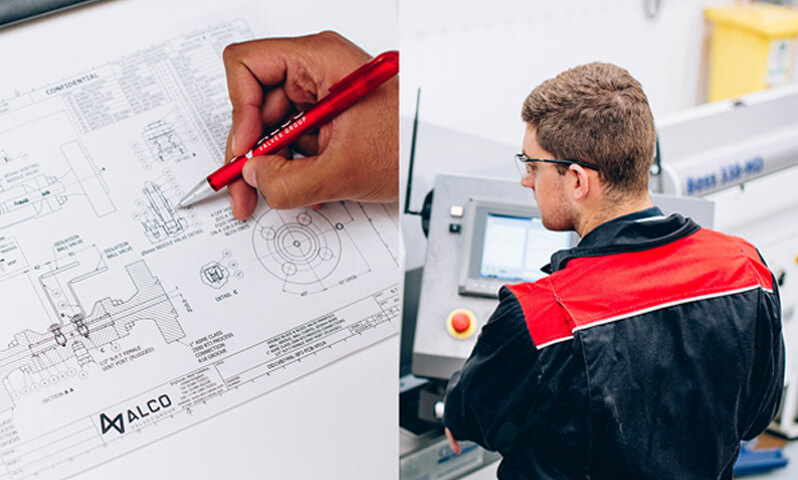

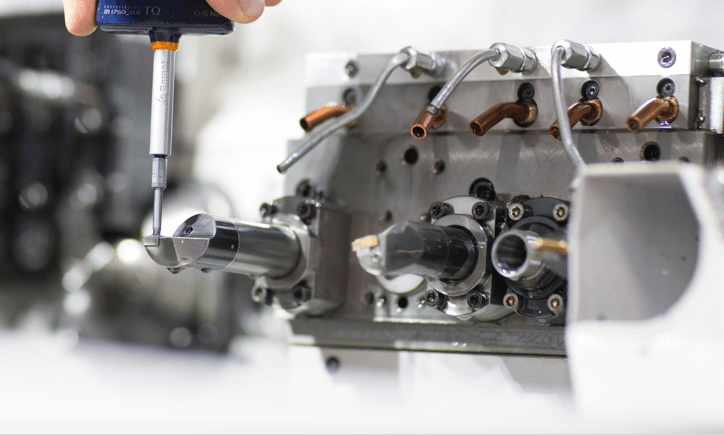

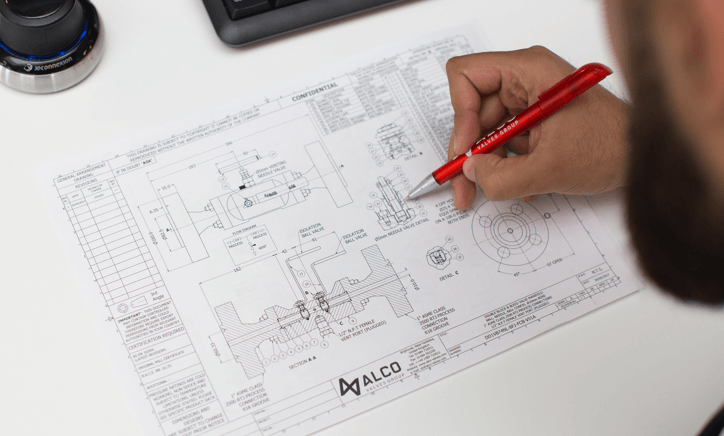

Our in-house valve manufacturing and testing facilities give us control over the full manufacturing process for our valves, and give you peace of mind over the quality of the finished product.

We can create valves to any design specification and with your choice of materials, within a very short lead time.

MANUFACTURING

Valve Testing & Compliance

Testing Standards

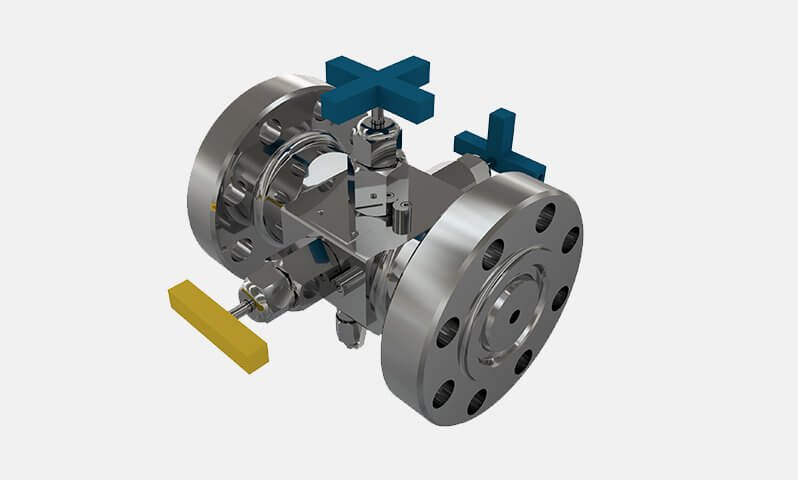

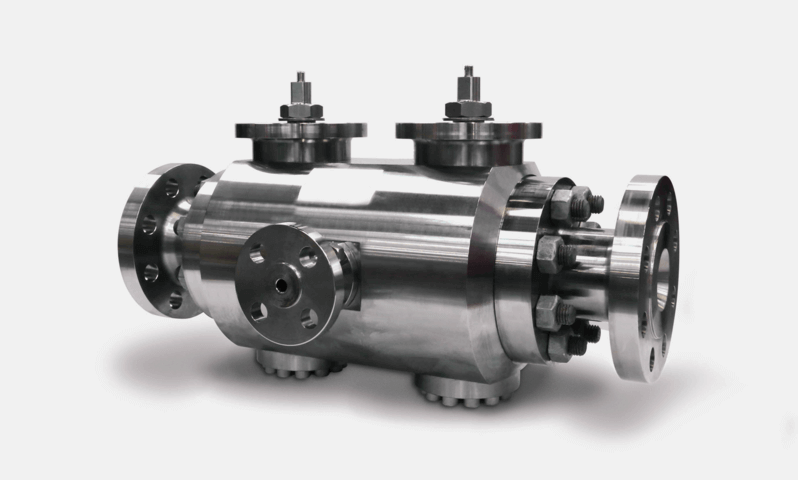

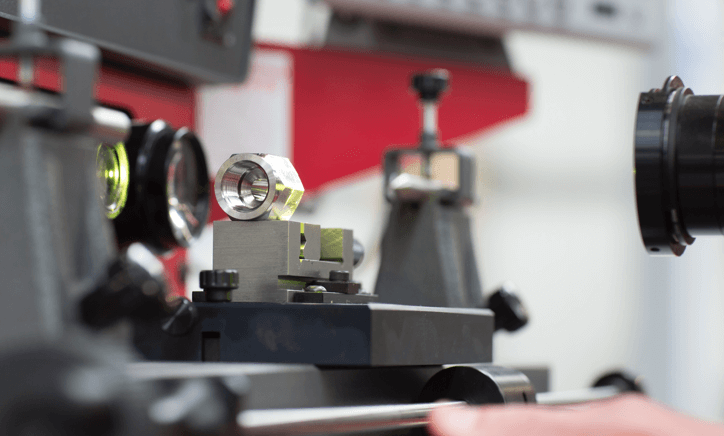

Our valves are subject to comprehensive testing to ensure that they can perform effectively in the relevant operating conditions. We recognise that lives can depend on the performance and reliability of our products and have invested heavily in the best testing facilities to give you greater peace of mind.

Our extensive facilities range from simple low-pressure testing for our more basic valves, to our new shock-resistant ballistic test bay. This bay enables us to replicate even the most demanding service conditions, with pressures of up to 60,000 psi for pipework and 21,500 psi for gas and hydro manifold valves.

All our testing bays include camera systems which enable us to record detailed footage of all tests, from a variety of angles simultaneously, to supplement the detailed findings of all testing activity.

All of our testing activity is extremely safe and adheres to HSE (Health & Safety Executive) recommendations for operator safety.

| Alco Valves Testing Includes |

|---|

| Ballistic Impact Testing | Destructive Testing (DVT) | ||

| Fugitive Emission Testing | Cycle Testing | ||

| Fire Testing | PR2 Testing | ||

| Hyperbaric Testing | Type Approval Testing | ||

| High/Low Temperature Testing | Endurance Testing | ||

| Hydrostatic Testing | Gas Testing | ||

| Torque Testing |