- Home

- Company News

- 6S Lean Manufacturing

26th February 2018

6S Lean Manufacturing

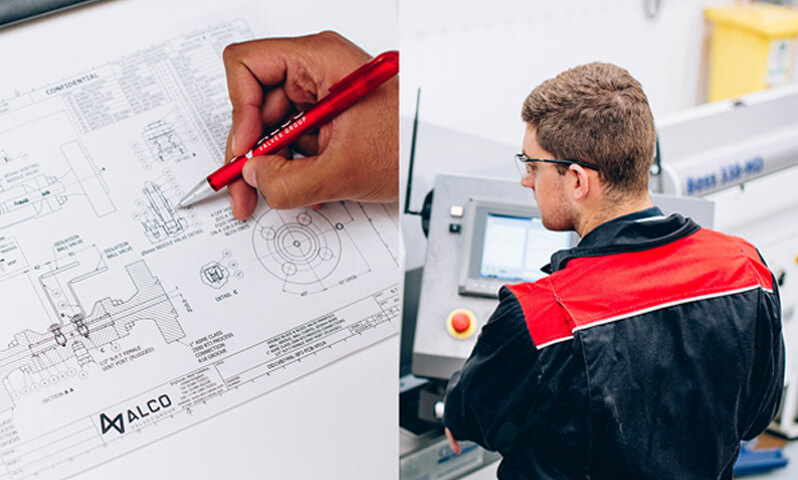

The Alco Valves Group Senior Management Team (SMT) work hard to identify and improve manufacturing practices and processes, increase efficiencies, decrease costs as well as make processes safer and better organised.

One such method that was implemented in early 2017 was a Lean manufacturing tool called 6S. The elements of 6S are simple but very effective. The 6 S’s include Safety, Sort, Set, Shine, Standardise and Sustain. Alco has worked to ensure that all areas of the business from the shop floor to the offices consider these 6 elements during regular audits.

As with any new and influential scheme there are always benefits, one being the improved safety metrics i.e. highlighting areas to improve and number of potential hazard spots. Another is that it involves all staff members working together to maintain the highest levels possible, whilst also working to drive continuous improvement, a subject of which both Alco and Graco are very enthusiastic. An example of this is how 6S has ensured that all essential equipment and tools etc are always close to hand and put back in the correct manner. Subsequently, the standards are extremely high and any visitors to the facility are always greatly impressed by how efficient, safe and organised each department on the site is.